Traditional spring houses offer you a natural, energy-efficient way to preserve dairy products using cold spring water. You'll find these structures maintain ideal temperatures between 35°F and 39°F through a simple but effective system of water circulation. As cold water flows through channels along interior walls, it creates a natural refrigeration effect that keeps milk, butter, and cheese fresh. You can store your dairy products in airtight containers placed directly in or near the flowing water channels, while the continuous water movement prevents stagnation and maintains consistent cooling. The centuries-old principles behind spring house preservation reveal fascinating insights about sustainable food storage.

Historical Origins of Spring Houses

Back in Colonial America, spring houses emerged as vital structures for food preservation and dairy processing. When early settlers searched for homestead locations, they'd prioritize finding a reliable natural spring, recognizing that access to clean, cold water would be essential for their survival and daily operations.

You'll find that spring houses were built to last, typically constructed from sturdy materials like fieldstone and masonry. Similar to historic buildings like the Spring House mansion with its hand-hewn timbers, these structures were crafted with exceptional attention to durability. Unlike other farm outbuildings that deteriorated over time, these structures endured thanks to their robust construction methods. The builders specifically chose stone over wood because it provided better insulation and could withstand the constant exposure to water and flooding.

If you'd visited a Colonial farm, you would've seen the spring house as part of a larger network of vital outbuildings. What made these structures particularly valuable was their dual purpose: they served as both a water source and a natural refrigeration system.

Most spring houses remained functional well into the 19th century, outlasting many other farm structures and becoming a defining feature of the rural American landscape. Their design proved so effective that they continued serving farms until modern refrigeration became widely available.

Spring Water Cooling Mechanics

You'll find that spring water cooling relies heavily on natural flow circulation, where cold water sinks while warm water rises in a continuous pattern.

To maintain effective temperature control, you need to take into account how the water's natural movement creates cooling zones, much like modern water coolers use gravity and thermal exchange principles. The system operates through a refrigeration process that efficiently reduces water temperature using a compressor and refrigerant.

The velocity of water flow plays a vital role in this process, as slower-moving water has more time to cool through contact with surrounding cold surfaces, similar to how an evaporator works in contemporary cooling systems.

Natural Flow Circulation Pattern

Through the ages, natural circulation patterns have proven to be remarkably efficient at cooling water without mechanical intervention. You'll find that successful cooling relies on a fundamental principle: warm water rises while cold water sinks, creating a continuous flow pattern. This process demonstrates thermal driving head effectiveness as the primary force behind fluid movement.

| Flow Factor | Impact |

|---|---|

| Temperature Gap | Greater differences create stronger circulation |

| Flow Path | Must remain clear and unobstructed |

| Heat Exchange | Requires constant heat source and sink points |

When you're examining a spring house's natural circulation, you'll notice that the cold spring water enters at a lower point while warmer water naturally rises to exit at a higher elevation. This circulation pattern works because of density differences – as water warms, it becomes less dense and rises, while cooler water's higher density causes it to sink and displace the warmer water.

You'll achieve the most effective cooling when you maintain proper elevation differences between your heat source and sink. It's critical to guarantee there aren't any blockages in the flow path, as these will disrupt the natural circulation. The system's efficiency depends on keeping a consistent temperature difference between the warm and cool areas.

Temperature Control Basics

Building on these natural circulation principles, understanding temperature control mechanics helps you implement effective cooling strategies.

You'll find that proper temperature regulation relies on a combination of direct and indirect cooling methods, similar to modern industrial systems but adapted for spring house use.

When you're managing a spring house, you'll need to work with both natural cooling processes and controlled circulation patterns.

For ideal temperature control in your spring house, consider these key mechanical elements:

- Water flow control through strategically placed channels that guide cool spring water along dairy storage containers, mimicking the function of industrial heat exchangers.

- Ventilation systems incorporating adjustable vents and shutters that you can modify based on external temperatures, working like automated temperature sensors.

- Circulation pathways designed with slight elevation changes that create natural pumping effects, similar to how process pumps move fluid in modern systems.

Water Velocity Effects

Naturally flowing water in spring house channels plays a critical role in the cooling mechanics of these traditional structures. You'll find the water moving through carefully designed channels along the interior walls, creating a consistent cooling effect that maintains temperatures around 50°F. This controlled flow serves as the heart of the spring house's preservation system.

| Aspect | Spring House Flow | Modern Coolers |

|---|---|---|

| Power Source | Natural water flow | Electricity |

| Maintenance | Channel cleaning | Technical repairs |

| Temperature Control | Passive cooling | Active cooling |

| Environmental Impact | Minimal footprint | Higher energy use |

The water's movement through these channels isn't just about transportation – it's a sophisticated cooling mechanism that you can rely on without mechanical intervention. As the water flows, it continuously absorbs heat from the surrounding air and stored items, creating a natural refrigeration effect. You'll notice this system's efficiency in how it maintains consistent temperatures throughout the structure, making it ideal for preserving dairy products, meats, and fruits. While modern cooling systems depend on complex machinery, you're getting the same preservation benefits through this ingenious use of natural water flow.

Building Materials and Construction

You'll need a solid stone foundation at least 18 inches thick to support your spring house walls and protect against water erosion.

When laying the stonework, you'll want to guarantee proper drainage channels are incorporated into the base structure while maintaining watertight integrity where the spring enters the building.

Your timber frame assembly should include rot-resistant woods like cedar or oak, fitted with precise joinery techniques to create a sturdy superstructure that can withstand constant moisture exposure.

Stone Foundation Requirements

When constructing a stone foundation, proper site preparation and materials form the cornerstone of a lasting structure. You'll need to start by clearing a level pad that extends at least 3 feet beyond your building's perimeter.

Set up batter boards and string lines to mark both the interior and exterior of your foundation trench, ensuring it's square using the Pythagorean theorem. The trench must reach the frost line with vertical, square sides.

For ideal stone placement in your foundation:

- Sort stones by size, selecting the largest for the bottom layer and specifically choosing corner stones with 90-degree angles.

- Position stones lengthwise into the wall, laying the exterior layer first followed by interior stones.

- Maintain a maximum joint width of 2cm between stones, using smaller pieces for inner layers.

You'll need to pour a concrete bed 10-15cm thick at the trench bottom, extending 15cm beyond the masonry on each side. Use Natural Hydraulic Lime mortar for underground work, keeping stones wet before placement.

The finished foundation should be at least 16 inches wide at the top, with the stem wall rising 18 inches above grade.

Timber Frame Assembly Methods

Moving up from the foundation to the building's framework, timber frame construction demands careful organization and precise execution.

You'll need to begin by organizing pre-labeled timbers into categories: bent materials, purlins, rafters, and connectors. Once your materials arrive on-site, arrange them strategically based on the assembly sequence.

Start by assembling the bents and trusses on the ground using come-alongs and pegs. You'll prepare these assembled sections for crane lifting by stacking them appropriately. Before lifting, verify you've cut posts to length and driven necessary pegs and structural screws into position.

When you're ready for lifting, attach taglines to keep the bents balanced as the crane positions them. You'll need to walk each bent into alignment and secure it with temporary bracing.

As you progress, install ridge beams and either purlins or rafters between the bents. Complete the assembly by connecting the bents with come-alongs and driving hardwood pegs into place.

You'll only remove the temporary bracing after you've secured all connectors. Don't forget to check that your frame is square and properly aligned before making final adjustments to verify structural integrity.

Dairy Storage Methods

Proper dairy storage revolves around four essential elements: temperature control, airtight containment, cooling systems, and safe handling practices.

You'll want to maintain temperatures between 35°F and 39°F for most dairy products, storing them on middle or lower shelves where temperatures remain most stable. It's important to use airtight containers to prevent odor absorption and maintain freshness, especially for items like cheese and yogurt.

For larger operations, cooling systems play an important role in preserving dairy products. You'll find bulk milk cooling tanks and plate heat exchangers working together to rapidly cool raw milk to 4°C, while instantaneous cooling systems provide swift temperature reduction through specialized heat exchangers.

- Picture a well-organized refrigerator with milk jugs stationed on the bottom shelf, maintaining ideal cooling at 35°F.

- Visualize sealed glass containers of yogurt, neatly arranged in the middle section, protected from absorbing other food odors.

- Imagine cheese properly stored in dedicated containers in the crisper drawer, maintaining perfect humidity levels.

Remember to return dairy products promptly to the refrigerator after use and avoid leaving milk at room temperature to prevent spoilage and maintain safety standards.

Natural Temperature Control Systems

Natural temperature control systems revolutionize dairy cooling through a combination of time-tested methods and modern engineering. You'll find these systems rely heavily on efficient heat exchange processes that maximize cooling while minimizing energy consumption.

When you're setting up a natural temperature control system, you'll want to incorporate plate heat exchangers that transfer heat between fluids without direct contact. They'll pre-cool your milk before it enters the bulk tanks, which greatly reduces the load on your primary cooling system.

You can pair this with cold water circulation through cooling coils, creating a steady and reliable cooling environment.

For enhanced efficiency, you'll benefit from implementing ice bank systems that provide thermal energy storage. These systems let you maintain temperatures close to water's freezing point, giving you maximum cooling power when you need it most.

You can also utilize falling film cooling with plates, which you'll find particularly cost-effective and easy to regulate. By combining these natural cooling methods with modern bulk tank technology, you're able to maintain the critical 4°C temperature needed to preserve milk quality while using fewer resources.

Spring House Design Features

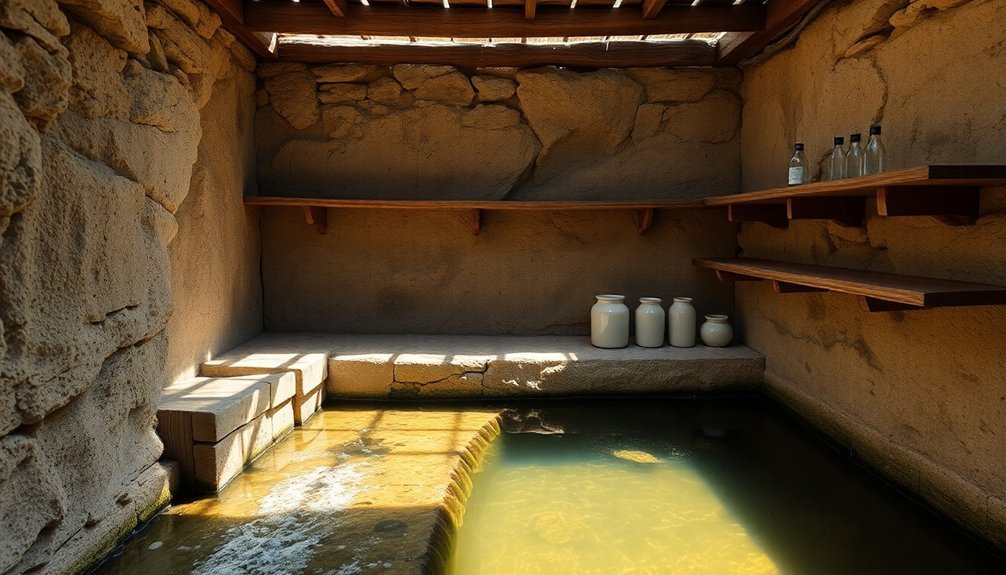

Spring house design represents a time-tested approach to cold storage that predates modern refrigeration. You'll find these structures built directly over natural springs, where the consistently cool water temperature creates an ideal environment for preserving perishable foods. The building's single-room layout, typically constructed from stone or concrete, maintains a steady internal climate while ensuring structural longevity.

Inside, you'll notice several practical design elements that maximize the spring's cooling properties:

- Stone troughs or channels carved into the floor, allowing cold spring water to flow through and cool stored items.

- Metal-lined storage tubs with secure lids built directly into the floor, creating designated spaces for dairy products and other perishables.

- Earthenware crocks strategically placed along water channels, taking advantage of the natural cooling system.

Whether you're using hand pumps or modern motorized systems to manage water flow, the spring house's design accommodates various methods of water access.

The structure's durable materials and solid foundation support heavy storage while protecting against environmental factors. You'll often find steel roofing added for extra durability, ensuring these essential structures continue serving their preservation purpose for generations.

Water Flow Management

Managing your cold water flow effectively requires precise control of flow rates between 0.5 to 1 gpm per storage unit to maintain ideal temperature preservation.

You'll need to adjust your water levels seasonally, lowering them during winter months to prevent freezing and increasing them during summer to maximize cooling capacity.

Installing sediment management systems, including filtered intake valves and settlement chambers, will protect your water quality and prevent buildup that could impact flow control efficiency.

Optimal Flow Rate Control

Effective flow rate control stands at the heart of cold water preservation systems, particularly in dairy operations where precise water-to-milk ratios are essential.

You'll need to maintain a 1:1 water-to-milk ratio for maximum cooling efficiency, with at least 30 gallons per minute (gpm) of water flow. If you're working with specialized precoolers, you might need to double this to a 2:1 ratio, requiring 60 gpm of water.

For ideal flow management in your dairy operation, consider these key visual elements:

- Variable Speed Drives (VSDs) mounted on milk pumps, displaying digital readouts and allowing real-time flow adjustments

- Flow meters showing the precise water-to-milk ratio, with clear markings for ideal ranges

- Digital control panels monitoring peak flow rates, calculated at 0.5 gpm per 10 cows for operations running more than 18 hours daily

You can enhance your system's efficiency by implementing programmable logic controllers to regulate valve cycles.

If you're operating an older farm with limited water capacity, installing VSDs offers a practical solution to manage flow rates while maintaining cooling effectiveness.

Remember to adjust your flow rates based on your specific operation's demands and equipment capabilities.

Seasonal Water Level Adjustments

Beyond controlling flow rates, seasonal water level adjustments require careful attention throughout the year.

You'll need to implement dynamic water level management that responds to changing weather conditions, soil moisture, and groundwater levels. Instead of fixed summer and winter levels, set variable water levels that adapt to your agricultural needs and prevent areas from becoming too wet or too dry.

When managing your spring house, you'll want to install adjustable flow splitters to maintain some flow in the source area while diverting water for your dairy operations.

Include seasonal shut-off valves to stop flow during non-grazing periods, and use diffuse discharge spring boxes with adjustable elbows to maintain ideal groundwater levels.

Don't forget to manage overflow pipes to return excess water to the spring channel.

Your water demand will fluctuate with seasons, particularly during hot months when heat abatement is essential.

You'll need to factor in varying consumption rates for lactating cows, heifers, dry cows, and calves.

Consider installing underwater drains to enhance dynamic level control, especially in peat land areas.

Always maintain backup water sources, such as secondary wells or storage tanks, to guarantee continuous water supply throughout seasonal changes.

Sediment Management Systems

Implementing proper sediment management systems stands as an important component of water flow control in dairy operations. You'll find that an effective sedimentation basin removes suspended solids while naturally filtering water through a floating mat of buoyant materials. This process not only reduces operational costs but also increases your lagoon capacity and decreases the frequency of sludge removal.

For ideal performance in your dairy's water treatment process, you'll need to follow these vital steps:

- Allow water to move slowly through presedimentation reservoirs, where heavy particles like sand and silt settle naturally to the bottom.

- Add coagulants such as aluminum sulfate to help consolidate suspended particles, followed by gentle stirring to distribute the chemicals.

- Direct the water through sedimentation basins for several hours, removing up to 85% of suspended materials.

You'll want to maintain proper water flow rates of 0.5 to 1 gpm per 10 cows while ensuring your surface water storage capacity can handle at least two years' worth of supply.

Don't forget to establish backup systems like secondary wells or storage tanks to maintain continuous operations during potential system failures.

Food Preservation Techniques

Various food preservation techniques have evolved throughout history to extend the shelf life of perishable items and maintain their nutritional value.

You'll find that heating and pasteurization are vital methods, where temperatures reach 70°C for 15-30 seconds to eliminate harmful bacteria, followed by quick cooling to 10°C to prevent bacterial regrowth.

When you're looking to store food long-term, freezing and cooling are effective options. While freezing won't kill microorganisms, it'll stop their growth at 0°F or below. You'll want to guarantee rapid, uniform cooling to minimize ice crystal formation and preserve food quality.

If you're interested in shelf-stable options, drying and dehydrating reduce water content to prevent spoilage. You can use various methods like sun drying, food dehydrators, or freeze-drying to create lightweight, portable foods that don't need refrigeration.

For added flavor and preservation, you might consider fermentation and pickling. You'll find that fermentation uses beneficial bacteria to produce preservative acids, while pickling employs agents like brine or vinegar.

These methods not only preserve your food but can also enhance its nutritional value and digestibility.

Modern Adaptations of Spring Houses

Through creative repurposing, traditional spring houses have evolved far beyond their original role as natural cooling stations. You'll find these historical structures reimagined as guest houses, art studios, and even unique event spaces for weddings.

While some still serve their original purpose on organic farms for dairy storage and produce cooling, many have been transformed to meet contemporary needs while preserving their architectural charm.

If you're considering adapting a spring house, you'll find modern improvements that enhance their functionality:

- Solar panels and rainwater collection systems for sustainability

- Updated insulation and ventilation systems for better climate control

- Modern plumbing and water management integration for improved efficiency

You can still leverage the natural cooling properties of spring houses for food preservation, especially during peak harvest seasons when main refrigeration units are at capacity.

They're particularly valuable for fermenting foods and storing specific types of produce. Educational opportunities abound as well, as these structures offer perfect settings for workshops on sustainable living and traditional farming methods, connecting modern generations to historical preservation practices.

Environmental Benefits of Spring Cooling

Beyond their architectural appeal and modern adaptations, spring houses offer remarkable environmental advantages that align perfectly with today's sustainability goals.

You'll find that spring houses considerably reduce energy consumption by utilizing natural cooling methods, eliminating the need for energy-intensive refrigeration systems. They're particularly effective at conserving water, as they work with existing groundwater flow rather than requiring additional water resources.

When you implement spring cooling methods, you're also contributing to greenhouse gas reduction. Unlike mechanical cooling systems that rely on electricity often generated from fossil fuels, spring houses use natural temperature regulation. This approach helps reduce your carbon footprint and supports climate resilience.

You can enhance these benefits by combining spring house principles with modern sustainable practices like heat recovery systems and renewable energy sources.

The climate resilience of spring houses is particularly valuable as temperatures rise. You'll appreciate how these structures maintain their cooling effectiveness regardless of external conditions, making them a reliable solution for dairy storage.

They're less vulnerable to power outages and mechanical failures, providing consistent cooling while minimizing environmental impact through reduced energy and water consumption.

Frequently Asked Questions

How Long Could Milk Typically Stay Fresh in a Spring House?

You'll find your milk stays fresh for several hours to a few days in a spring house, depending on water temperature. If you maintain temperatures below 10°C, you can preserve milk quality longer.

What Alternative Cooling Methods Were Used When Springs Weren't Available?

When you didn't have springs, you could use windmill-pumped well water, stone-lined stream channels, ice storage, or place your dairy on a building's shaded northern side to keep milk cool.

Could Spring Houses Be Used Effectively in Different Climate Zones?

You'll find spring houses work effectively across various climate zones since they use natural insulation, maintaining cool temperatures year-round. Their adaptable designs let you utilize hillsides, stone materials, and water sources for consistent cooling.

How Did Families Maintain Water Quality in Their Spring Houses?

You'd maintain spring house water quality by diverting surface runoff, fencing the area to prevent contamination, testing regularly for bacteria, disinfecting with chlorine when needed, and keeping storage containers clean and sealed.

What Determined the Ideal Distance Between a Home and Spring House?

You'd want your spring house close enough for convenient daily access but far enough to avoid household contamination – typically 50-100 feet away, considering drainage patterns and natural ground slope for ideal functionality.

In Summary

You'll find that spring houses represent an elegant fusion of nature's cooling power and human ingenuity. Whether you're preserving dairy products or adapting these time-tested methods for modern use, you're tapping into a sustainable practice that's served communities for centuries. By understanding the principles of water-based cooling and natural temperature control, you're able to reduce energy consumption while maintaining traditional food preservation techniques.

Leave a Reply