Artisanal cheese gets better with time because of carefully controlled aging environments and natural microbial development. You'll find that traditional aging caves maintain steady temperatures around 55°F with humidity above 90%, creating perfect conditions for beneficial molds and bacteria to flourish. These microorganisms break down proteins and fats, developing complex flavors and aromas that you can't replicate in mass production. Regular turning of cheese wheels and proper humidity control guarantee even aging, while specialized affineurs (cheese agers) monitor every step of the process. The ancient wisdom behind these techniques holds secrets that continue to shape modern artisanal cheesemaking.

Ancient Cheese Aging Techniques

Throughout history, cheese aging has been a meticulous art form that relies heavily on natural environments and time-tested techniques.

You'll find that ancient cheesemakers discovered the perfect conditions in underground limestone caves, where consistent temperature and humidity created ideal environments for developing complex flavors and textures.

When you explore medieval monasteries, you'll see how monks perfected these aging techniques, particularly for cheeses like Brie and Camembert.

They used specific materials that profoundly influenced the final product – wood boards for developing unique rinds, copper vats for precise temperature control, and clay pots for making acid-heat coagulated cheeses. The traditional practice of using wood aging boards continues to be crucial for developing distinctive characteristics in cheeses like Parmigiano.

The physical handling of cheese was equally important.

You'd need to turn cheese wheels regularly to guarantee even maturation and prevent misshaping. This careful rotation helped distribute moisture and fats uniformly, especially in larger wheels.

The Romans' experimentation with different milk types and aging methods laid the groundwork for modern artisanal cheese making.

Today, you'll still find these time-honored techniques being used by artisanal cheesemakers who understand that authentic aging processes are essential for maintaining the quality and character of their cheeses.

Natural Microbial Development

A complex ecosystem of microorganisms drives the transformation of milk into artisanal cheese, with natural microbial cultures playing a significant role. You'll find that traditional cheese makers harness these microbes through enriched raw milk (eRM) and natural whey cultures (NWC), creating diverse microbial communities that enhance cheese quality. Traditional producers often rely on natural selective pressures to promote the dominance of beneficial lactic acid bacteria in their cultures.

| Process Stage | Key Microorganisms | Primary Function |

|---|---|---|

| Initial Fermentation | Lactic Acid Bacteria | Lactose to lactic acid conversion |

| Curd Formation | Streptococci, Lactobacilli | Acidification and protein coagulation |

| Early Ripening | Secondary bacteria | Flavor compound development |

| Surface Development | Fungi, yeasts | Rind formation |

| Final Maturation | Mixed microbiota | Texture and aroma refinement |

When you're examining artisanal cheese production, you'll notice that LAB are essential in the early stages, metabolizing lactose and driving curd formation. As the cheese ages, secondary microbiota develop both within and on the surface, creating distinctive rinds and contributing to the cheese's character. Through backslopping and careful culture maintenance, you're preserving these complex microbial communities that give artisanal cheeses their unique regional qualities and authentic flavors.

Temperature Control Mastery

The mastery of temperature control stands as a cornerstone of successful artisanal cheesemaking. As cheese makers refined their understanding of temperature's role, they discovered how precise control could dramatically improve their craft.

You'll find that each stage demands specific temperatures: from pasteurization at 72°C to the delicate addition of cultures between 20-55°C, depending on whether you're using mesophilic or thermophilic strains.

When you're adding rennet, you'll need to maintain temperatures between 30-40°C for ideal coagulation. Curd cooking temperatures vary by cheese type – you'll cook cheddar curds at 38°C, while parmesan requires temperatures up to 50°C. Regular temperature monitoring twice daily ensures consistent and optimal results during the aging process.

Getting these temperatures wrong can lead to weak curds, off-flavors, or even safety concerns.

Today's artisans rely on precise digital thermometers, temperature-controlled vats, and PID controllers to maintain these essential temperatures.

You'll find that proper temperature control prevents costly mistakes like inconsistent curd formation or texture damage. It's not just about following numbers – it's about understanding how temperature affects protein coagulation, moisture content, and enzyme activity.

This knowledge has transformed artisanal cheesemaking from an imprecise art into a refined craft.

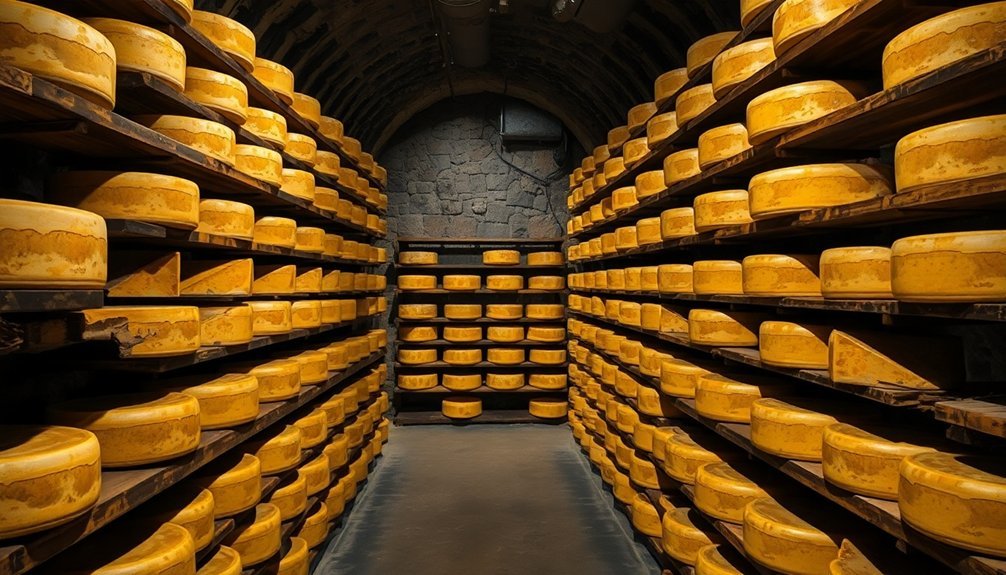

Traditional Aging Caves

Every traditional aging cave serves as nature's perfect cheese vault, maintaining steady temperatures around 55°F and humidity levels above 90%.

You'll find these natural chambers perfectly suited for cheese aging, as they provide consistent conditions that allow cheeses to develop complex flavors and textures over time.

The magic of cave aging lies in its ability to support natural microflora growth while protecting the cheese throughout its maturation.

When you're aging different cheese varieties, you'll need to reflect on their unique requirements:

- Soft-ripened cheeses like Brie need just 3-5 weeks in bloomy rind caves

- Hard Alpine-style cheeses demand months or even years of careful aging

- Washed rind varieties require regular baths in water, beer, wine, or brine

- Natural rind cheeses develop their protective exterior through cave conditions

- Specialized cheeses, like Roquefort, must age in specific geographic locations

You'll find the aging process requires constant attention, with regular turning, weighing, and tasting to guarantee proper development.

While many modern facilities now replicate these conditions artificially, traditional caves continue to demonstrate why they've been trusted for centuries in producing exceptional artisanal cheese.

Mountain Cheese Making Methods

Deep in mountain chalets and alpine dairies, traditional cheese making methods have endured for centuries, combining precise temperature control with time-tested techniques. You'll find artisans carefully warming fresh milk in wood-fired or stainless steel vats, ensuring the perfect temperature to preserve natural bacteria. They'll add specific cheese cultures that transform lactose into lactic acid, developing distinct flavors and textures.

The process becomes more intricate as you watch them add rennet to coagulate the milk. For Alpine cheeses, they'll cut the curds into tiny rice-sized pieces, a vital step that removes more moisture than standard cheese making. You'll notice the careful stirring and heating that follows, as craftsmen monitor the precise moment to drain the whey.

| Stage | Mountain Method | Impact on Cheese |

|---|---|---|

| Heating | Wood-fired vats | Traditional flavor |

| Cutting | Rice-sized curds | Lower moisture |

| Draining | Enhanced pressure | Firmer texture |

| Shaping | Large wheel molds | Classic form |

| Aging | Daily brine brush | Robust rind |

The final steps involve pressing these curds into distinctive large wheels, where they're flipped and brushed with brine daily, developing their characteristic mountain cheese rind.

Artisanal Flavor Development

Once cheese wheels are shaped and pressed in mountain dairies, complex biochemical processes begin transforming them into distinctive artisanal creations.

You'll find that microbes and enzymes work together in a fascinating dance of flavor development, breaking down proteins, fats, and sugars into compounds that give artisanal cheese its unique character.

The key processes you'll discover in artisanal cheese development include:

- Glycolysis, where lactic acid bacteria convert lactose into lactic acid, setting the stage for flavor development

- Proteolysis, which breaks down proteins into smaller peptides, creating rich, complex tastes

- Lipolysis, releasing fatty acids that transform into distinctive aromatic compounds

- Citrate metabolism, particularly important in Dutch-style cheeses

- Enzymatic activities that continue throughout the aging process

During aging, you'll notice how environmental factors like temperature and humidity play significant roles.

As you watch your cheese mature in aging rooms, regular turning guarantees even development from rind to core.

The longer you age your cheese, the more pronounced these biochemical transformations become, resulting in deeper flavors and more complex aromas that you can't find in mass-produced varieties.

Regional Aging Practices

Throughout the world of artisanal cheese-making, natural caves and carefully controlled aging rooms serve as vital environments for developing complex flavors and textures.

You'll find that traditional cheese makers rely heavily on these natural environments, where stable temperatures and humidity levels create perfect conditions for aging varieties like Roquefort.

You can observe how regional practices have evolved differently across various locations. In the Swiss Alps, producers follow time-honored methods of rubbing Emmental wheels with salt brine before aging them in mountain caves.

European monasteries have become important centers for cheese refinement, where monks have perfected aging processes and bacterial cultures over centuries.

When you're exploring artisanal cheese production, you'll notice that maintaining proper conditions requires constant attention.

Producers must regularly turn cheese wheels to guarantee even distribution of moisture and prevent misshaping. They'll also wash rinds with water or salt brines to avoid drying and cracking.

These practices vary by region and cheese type, with each area developing unique techniques based on their geographical conditions and cultural heritage.

Family recipes, passed down through generations, continue to influence these local aging methods.

Time-Tested Preservation Methods

Traditional preservation methods in artisanal cheese-making rely on a delicate balance of natural ingredients and time-honored techniques.

You'll find that these methods have evolved over generations to create cheeses that not only last longer but develop more complex flavors over time.

At the heart of preservation is the careful manipulation of environmental factors and natural ingredients.

When you're preserving artisanal cheese, you're working with living cultures and beneficial bacteria that transform raw milk into distinctive varieties.

The process involves controlling humidity, temperature, and air circulation while allowing nature to do its work.

Key preservation techniques that you'll encounter include:

- Using unpasteurized milk to maintain natural enzymes and beneficial bacteria

- Hand-turning cheese wheels regularly to guarantee even aging

- Developing natural rinds that protect and enhance the cheese

- Monitoring specific cave or aging room conditions

- Maintaining precise moisture levels through careful curd handling

Cooperative Aging Systems

You'll find that cooperative aging systems revolutionized mountain cheese production by creating networks of shared aging facilities where farmers could send their fresh cheeses while staying with their herds.

These collaborative networks provided cost-effective quality control through standardized aging processes and shared expertise among affineurs.

The system's efficiency meant farmers could focus on production while specialized aging facilities maintained precise environmental conditions for ideal microbial development.

Cost-Efficient Quality Control

Modern artisanal cheese producers' greatest challenge lies in maintaining quality while managing costs, which has given rise to cooperative aging systems.

You'll find that these systems leverage shared infrastructure and expertise to guarantee consistent quality across all producers' cheeses while considerably reducing individual operating expenses.

When you work with cooperative aging facilities, you'll benefit from dedicated affineurs who bring specialized knowledge to the aging process.

These experts maintain precise environmental controls and monitor your cheese's development, guaranteeing ideal conditions for flavor development.

Here's what makes cooperative aging systems so effective:

- Access to state-of-the-art aging facilities without bearing the full cost burden

- Professional affineurs who understand microbial development and cheese health

- Standardized processes that assure consistent quality across batches

- Controlled environments with precise temperature and humidity management

- Shared resources that reduce individual financial risk

The combination of technological advantages and pooled expertise means you're getting professional-grade aging services at a fraction of the cost.

For small-scale producers, this makes the difference between struggling with inconsistent quality and delivering reliably exceptional artisanal cheese.

Mountain Cheese Storage Networks

The cooperative aging system's roots trace back to Europe's mountain regions, where farmers faced unique challenges in cheese production. While farmers needed to stay with their herds in the mountains, they couldn't properly age their cheese there. This led to the development of communal aging facilities in the valleys, managed by skilled affineurs who could maintain ideal conditions for various cheese types.

You'll find this system particularly essential for Swiss-style cheeses, which demand a complex dual-temperature aging process. These cheeses require warm rooms (70°F) for proprionic bacteria development, followed by cooler environments (55°F) for extended aging. Since maintaining multiple temperature-controlled rooms isn't feasible for individual farmers, cooperative facilities provide the perfect solution.

In these shared aging spaces, you'll see green cheese from multiple mountain farms being aged together under precise environmental controls. The facilities handle everything from cleaning and flipping to specialized temperature and humidity management.

This cooperative approach has proven so successful that it's now the standard for traditional mountain cheeses like Beaufort, Emmentaler, Comté, and Manchego, resulting in consistently high-quality products with complex flavor profiles.

Surface Mold Cultivation

You'll find that surface mold cultivation requires precise humidity control, with higher levels needed in the early stages to encourage proper growth of white-rind forming cultures like Penicillium candidum and Geotrichum candidum.

As these beneficial molds develop on your cheese's surface, they'll create the distinctive white bloomy rind that characterizes Brie and Camembert styles.

Your cheese's flavor profile will transform over time as the molds break down fats and proteins, producing complex buttery and mushroomy notes that intensify with age.

Controlled Humidity Effects

Controlling humidity levels stands as a cornerstone in artisanal cheese aging, particularly for cultivating desirable surface molds. When you're aging cheese, maintaining precise humidity helps balance moisture content while supporting enzymatic processes that develop complex flavors.

You'll find that different cheese varieties require specific humidity ranges, with soft-ripened cheeses needing 90-95% relative humidity and hard cheeses thriving at 75-80%.

Here's what proper humidity control achieves in cheese aging:

- Promotes beneficial mold growth while preventing unwanted varieties

- Regulates moisture loss, determining whether cheese becomes creamy or crumbly

- Supports enzymatic breakdown of proteins and fats for flavor development

- Guarantees proper rind formation through controlled surface conditions

- Prevents condensation that could lead to uneven aging

You can maintain ideal humidity using various methods, from simple water trays to sophisticated automated systems.

If you're working with soft-ripened cheeses, you'll need higher humidity levels for proper rind development, while hard cheeses require lower levels to concentrate flavors through controlled moisture loss.

Temperature and humidity work hand in hand – as temperatures rise, you'll need to adjust humidity levels accordingly to maintain the perfect aging environment.

White Rind Development

Mastery of white rind development forms the heart of creating soft-ripened cheeses like Brie and Camembert.

You'll find that the process begins with inoculating the cheese with *Penicillium candidum* and sometimes *Geotrichum candidum*, which create that characteristic bloomy white surface you've come to recognize.

You need to maintain precise environmental control to cultivate these rinds properly.

You'll move your cheeses between rooms with different climate conditions and turn them almost daily to guarantee even mold distribution. As the mold develops, you'll see it start as tiny white spots before it spreads into a complete snowy coating.

The affineur's role is essential – they'll pat down the fuzzy mold growth and occasionally wash the cheese with brine to encourage proper development.

You can't rush this process; it requires constant monitoring and adjustment. As the mold breaks down fats and proteins, it transforms both the texture and flavor of your cheese.

You'll notice the rind might shift from pure white to grayish as it matures, but don't worry – this is natural.

The key to success lies in favoring natural rind development over industrial shortcuts like preservatives or antifungal treatments.

Flavor Profile Evolution

The intricate dance of surface mold cultivation shapes every aspect of a cheese's flavor development. As *Penicillium* and other beneficial molds grow on your cheese's surface, they'll break down fats and proteins, creating a complex symphony of flavors that you won't find in younger cheeses.

The controlled environment of aging rooms allows these molds to thrive, transforming simple milk proteins into rich, nuanced taste experiences.

You'll notice these remarkable changes in your cheese's character through:

- Buttery and mushroomy notes emerging as the mold breaks down surface proteins

- Texture evolution from firm to silky or oozy, especially in soft varieties

- Development of tangy undertones as the aging process continues

- Color changes from bright white to subtle grayish-brown hues

- Increasingly complex aroma profiles that signal proper maturation

Daily turning and periodic brushing guarantee even mold distribution and controlled growth across your cheese's surface.

Different aging chambers, each with their unique temperature and humidity levels, help guide this transformation. Over time, you'll experience how these carefully managed conditions allow the cheese to develop its full potential, with some varieties maturing for up to 24 months to achieve their peak flavor complexity.

Humidity Control Legacy

Ancient cheese caves hold secrets of humidity control that modern artisans still emulate today. These natural environments maintained consistent humidity levels between 75-95% relative humidity, creating ideal conditions for cheese aging that we now replicate using modern technology.

You'll find that today's cheese makers use a combination of traditional wisdom and contemporary methods to achieve perfect humidity control. They've learned that different cheeses demand specific moisture levels – from Cheddar requiring below 80% RH to semi-hard cheeses needing 90% RH during fermentation.

When you're aging cheese, proper humidity prevents unwanted moisture loss while supporting beneficial microorganism growth.

Modern humidity control systems have revolutionized what was once left to nature. You can now precisely regulate moisture levels using ultrasonic misters, steam humidifiers, or even simple water trays for smaller operations.

These tools help you maintain the delicate balance that affects everything from rind formation to flavor complexity. Whether you're working with Emmentaler at 85-90% RH or storing Gouda at 75-80% RH, you'll find that proper humidity control is essential for developing the texture and taste that make artisanal cheeses exceptional.

Proteolysis Through Ages

You'll find proteolysis at work in artisanal cheese as it breaks down long protein chains into smaller peptides and amino acids, creating the complex flavors you've come to love.

Throughout aging, you can taste how this process transforms proteins into distinct flavor compounds like smoky and nutty notes, while simultaneously affecting the cheese's texture.

When you examine aged cheeses closely, you'll notice how proteolysis influences crystal formation, particularly in varieties like aged Gouda and Parmesan, where these crystals contribute to both texture and taste.

Breaking Down Protein Chains

Throughout the aging process, proteolysis stands as one of the most vital biochemical transformations in cheese-making. When you're making cheese, this complex process begins with coagulants breaking down large protein chains into smaller peptides.

As time progresses, starter bacteria and non-starter lactic acid bacteria continue this breakdown, creating even smaller protein fragments that notably influence your cheese's character.

You'll notice these key changes during proteolysis:

- The cheese's texture evolves from rubbery to homogeneous in the first weeks

- Meltability increases as the casein network breaks down

- The stretch of your cheese may decrease due to protein network disruption

- Salt levels directly impact the rate of protein breakdown

- Temperature and moisture content control the speed of aging

Understanding these factors helps you control the aging process. If you're aiming for slower proteolysis, you might use higher cooking temperatures, as seen in Swiss or Parmesan production.

The moisture content and pH of your cheese play vital roles too – lower moisture and specific pH ranges (below 5.06 or above 5.15) enhance both primary and secondary proteolysis, leading to more complex flavors and textures.

Flavor Compound Development

The complex journey of flavor development in cheese begins with proteolysis, where enzymes systematically break down proteins into smaller compounds that create distinct taste profiles.

You'll find that this process isn't working alone – it's part of a trio of biochemical stages alongside glycolysis and lipolysis, each contributing unique flavor compounds to your cheese.

As your cheese ages, microorganisms play a vital role in developing its character. The enzymes they release, particularly from starter bacteria and non-starter lactic acid bacteria, break down the casein network and create distinctive flavor compounds.

If you're using raw milk, you'll benefit from indigenous microflora that add even more complexity to the flavor profile.

The development of these flavors isn't random – it's heavily influenced by factors you can control. The moisture content, pH level, and aging temperature all affect how proteolysis progresses.

When pH stays between 5.06 and 5.15, you'll get ideal flavor development.

Even your choice of milk matters – whether it's from grass-fed or grain-fed cows, pasteurized or raw, these decisions shape the final flavor compounds that emerge during aging.

Crystal Formation Impact

As cheese ages and proteins break down through proteolysis, a remarkable transformation occurs beneath the surface – the formation of distinctive crystals.

You'll find two main types: calcium lactate crystals, which develop when good bacteria break down lactose into lactic acid, and tyrosine crystals, which form as proteins decompose and release amino acids.

These crystalline formations aren't just scientific curiosities – they're markers of quality that enhance your cheese-eating experience.

When you bite into a well-aged cheese, you'll notice:

- A delightful crunch that contrasts with the smooth cheese texture

- Bright white specks throughout the cheese's interior

- Complex flavor development around the crystal formations

- Different crystal patterns depending on the cheese type

- A satisfying texture that indicates proper aging

The crystal formation process depends heavily on your cheese's environment.

Moisture levels, storage temperature, and starter cultures all play significant roles in determining crystal development.

In moist cheeses like aged Cheddar, you'll typically find softer calcium lactate crystals, while drier varieties like aged Parmesan develop firmer tyrosine crystals throughout their interior.

Traditional Rind Formation

Deep in traditional cheese caves, master cheesemakers begin the intricate process of rind formation by treating fresh wheels of pressed curds with either a salt-water brine or dry salt rub.

You'll find these wheels aging in carefully controlled environments with humidity levels between 90-98%, preventing the rinds from cracking while promoting natural microbial growth.

As you watch the cheese develop, you'll notice the formation of a complex microbial community on its surface. These microorganisms break down fats and proteins, creating distinctive textures and flavors.

Even cheese mites play their part, creating tiny holes that enhance aeration and contribute to the final product's character.

You'll see cheesemakers maintain these wheels through weekly brushing and flipping, ensuring even ripening and controlled mold development.

They'll often move cheeses between different atmospheres to encourage specific microbial growth patterns.

The result? You'll discover rinds with beautiful brown and silver hues, mottled with white to brown molds.

These edible rinds don't just protect the cheese – they'll add deep, earthy, and mushroom-like flavors that enhance the cheese's overall profile, making each wheel uniquely complex and flavorful.

Frequently Asked Questions

How Does Genetics of Dairy Animals Affect Cheese Aging Quality?

Your dairy animal's genetics influence cheese aging through specific milk proteins and fat content. You'll get better aging qualities when your cows have favorable κ-CN β alleles and higher levels of long-chain fatty acids.

Can Modern Technology Enhance Traditional Cheese Aging Without Compromising Authenticity?

Yes, you'll find modern technology enhances traditional cheese aging through precise climate control and monitoring systems, while still preserving authentic methods. It simply makes the process more reliable without changing fundamental artisanal techniques.

What Role Does Soil Composition Play in Cave-Aged Cheese Flavors?

You'll find that soil composition directly influences your cheese's flavor through its minerals and water content. It affects the cave's microbiome and transfers distinct earthy notes to your aging cheese through moisture absorption.

How Do Seasonal Variations in Milk Affect the Final Aged Cheese?

You'll notice seasonal milk changes dramatically affect your aged cheese. Summer milk creates milder flavors with golden hues, while winter milk produces richer textures and complex flavors due to higher fat and protein content.

Does Aging Cheese at Different Altitudes Produce Distinct Flavor Profiles?

Yes, you'll find that different altitudes create unique cheese flavors. When you age cheese at higher altitudes, you'll get sweeter, nuttier tastes due to specific microbial activity and environmental conditions.

In Summary

You'll find that time has perfected artisanal cheese through centuries of refined aging techniques. From the natural microbial environments in traditional caves to the precise control of temperature and humidity, cheesemakers have mastered these elements to enhance flavor development. You're tasting the results of proteolysis and careful rind cultivation that our ancestors discovered and modern artisans continue to perfect through time-honored methods.

Leave a Reply