Ash aging creates new flavors in your food through multiple chemical and biological processes. When you apply food-grade ash, it lowers surface acidity and creates ideal conditions for beneficial bacteria to thrive. This triggers important chemical reactions, particularly the Maillard reaction between proteins and sugars, which produces complex flavor compounds. The ash's ability to control moisture and pH levels also encourages specific enzymatic reactions that develop unique taste profiles. As the aging process continues, you'll notice how the combination of microbial activity, chemical transformations, and controlled environments produces increasingly sophisticated flavors. There's a fascinating world of traditional and modern techniques behind this ancient preservation method.

The Ancient Practice of Ash

Today's ash-aging process has evolved greatly.

You're not dealing with regular barbecue charcoal but rather specialized food-grade ash made from burned plant matter or activated charcoal. It's a refined ingredient that's odorless, tasteless, and completely sterile.

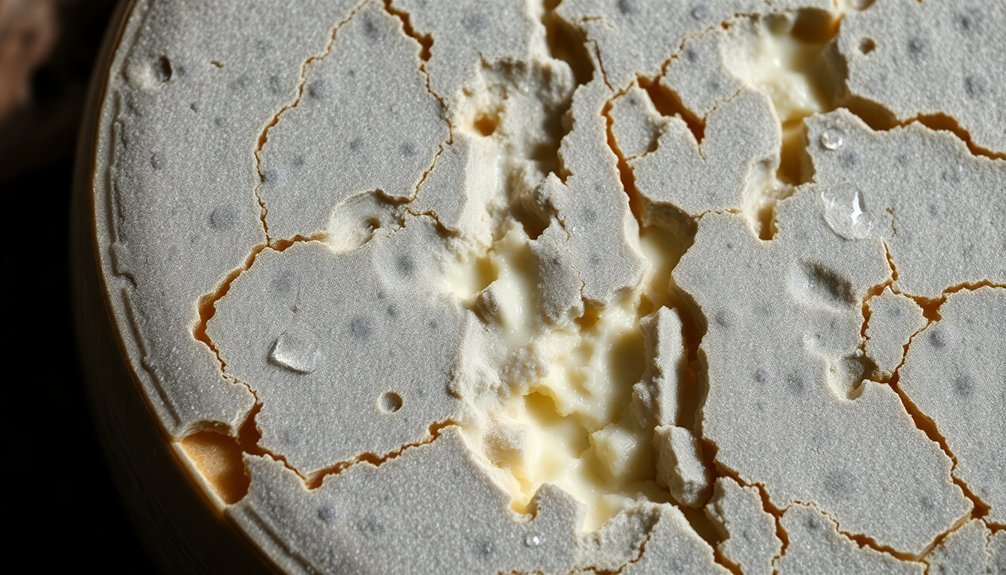

When you're examining modern ash-treated cheeses, you won't detect any grittiness – the ash integrates seamlessly into the cheese's texture, often mixed with salt for best application.

This ancient practice has transformed into a sophisticated technique that continues to enhance cheese production worldwide. The ash significantly lowers surface acidity, creating ideal conditions for cheese ripening.

Chemical Reactions During Aging

The science behind ash aging reveals complex chemical transformations, with Maillard reactions leading the way. When you age food in ash, you're creating an environment where reactive sugars and proteins interact at specific moisture levels, typically between 0.4-0.8 water activity. These reactions transform your food's flavor, color, and texture through a series of chemical processes.

During aging, you'll find that proteins undergo significant changes as their lysine and arginine components react with sugars. This creates new compounds like CML, CEL, and pentosidine, which contribute to the unique flavors you taste in ash-aged foods. The process also forms melanoidins, responsible for the characteristic browning you'll observe. Similar to how high-temperature cooking generates potentially harmful compounds, these reactions require careful monitoring.

What's fascinating is how environmental factors control these reactions. The metal ions present in ash can influence reaction rates, while pH levels affect how sugars break down.

You'll notice that temperature plays a vital role too – warmer conditions speed up these transformations. While these reactions create appealing flavors and aromas, they're also forming AGEs, which can impact the food's nutritional value and digestibility.

That's why understanding and controlling these reactions is essential for ideal aging results.

Microbial Growth and Development

Microbial communities thrive in ash-enriched environments, creating complex ecosystems that influence food aging. When you add ash to food aging environments, you'll notice increased bacterial growth, particularly from genera like Bacillus and Pseudomonas. These microorganisms flourish because ash raises pH levels and provides essential macronutrients. Studies show that biomass ash applications increase bacterial counts up to 9.0 × 10^6 CFU/g in enriched soils.

You'll find that moisture plays an important role in this process. Higher moisture levels combined with ash create ideal conditions for beneficial bacteria to multiply, leading to unique flavor development during aging. The ash-induced changes also stimulate nitrogen mineralization, which supports microbial growth and metabolic activities.

| Microbial Factor | Impact on Flavor Development |

|---|---|

| Bacterial Growth | Produces complex enzymes that break down proteins |

| pH Changes | Activates specific bacterial strains for fermentation |

| Nutrient Release | Enables production of flavor compounds |

| Moisture Level | Controls microbial activity rates |

| Community Structure | Determines final flavor profile diversity |

The microfood web structure changes greatly with ash application, affecting how flavors develop. You'll see variations in microbial populations based on seasonal changes and environmental conditions, which directly influence the aging process and resulting taste profiles.

Ph Balance and Flavor Formation

You'll notice that ash-aging creates an alkaline environment that fundamentally alters the taste chemistry of foods by mellowing certain flavors while intensifying others.

The higher pH levels typical in ash-aging promote specific enzymatic reactions and influence protein structures, leading to unique flavor compounds you won't find in traditional aging methods.

The controlled microbial activity within this alkaline environment produces beneficial compounds that enhance umami flavors and contribute to the food's distinctive taste profile.

Alkalinity Changes Taste Chemistry

Chemistry's role in taste transformation becomes evident when examining how alkalinity affects food's flavor profile. When you introduce alkaline substances to food, they fundamentally alter how you perceive its taste. At pH levels above 8.5, you'll notice a distinctive coating sensation in your mouth, which directly impacts how flavor compounds dissolve and interact with your taste buds.

Your body's recently discovered Alka receptor helps detect these alkaline conditions, forming chloride ion channels that respond to hydroxide ions. This mechanism isn't just about taste – it's a crucial safety system that helps you avoid potentially harmful high-pH substances.

When you're eating traditionally alkaline-processed foods like nixtamalized corn or ramen noodles, you're experiencing carefully controlled pH levels that enhance rather than harm.

The alkalinity in ash-aging doesn't just create new flavors; it balances existing ones. You'll find it working to offset richness, enhance freshness, and create complex flavor profiles through its interaction with acidic components.

This chemical dance affects everything from the solubility of taste compounds to the overall harmony of flavors in your food.

Microbial Activity Enhances Flavors

The dynamic world of flavor enhancement through microbial activity reveals itself in every fermented food you enjoy. When microbes break down carbohydrates, proteins, and lipids in ash-aged foods, they're creating complex flavor compounds through their metabolic processes.

You'll find that starter cultures like Lactobacillus and Streptococcus work together, enhancing each other's abilities to produce distinctive flavors through their enzymatic activities.

In ash-aged foods, these microorganisms thrive in the alkaline environment, producing unique flavor profiles through their interactions. They're constantly breaking down nutrients and creating new compounds that contribute to the food's final taste and aroma characteristics.

- Proteolytic enzymes break down proteins into flavor-rich amino acids

- Lipolytic enzymes transform fats into aromatic fatty acids

- Bacterial interactions create complex flavor compounds through mutual benefits

- Fermentation enhances nutrient bioavailability, affecting flavor perception

You'll notice that the textural changes these microbes create also influence how you experience the flavors. As they modify proteins and fats, they're not just changing taste – they're transforming the entire sensory experience of ash-aged foods through their metabolic activities.

Surface Moisture Control

Surface moisture control in ash-aging processes stands out as an essential factor for developing unique flavors and maintaining food quality. You'll find that proper moisture levels influence not just taste but also texture, shelf life, and safety of your ash-aged foods.

| Moisture Factor | Impact on Food |

|---|---|

| Water Activity | Affects microbial growth and chemical reactions |

| Packaging Type | Controls moisture exchange with environment |

| Storage Climate | Influences moisture retention and loss |

| Temperature Range | Determines rate of moisture-related reactions |

| Monitoring Methods | Guarantees consistent quality control |

When you're aging foods in ash, you'll need to maintain specific moisture levels to promote desired chemical reactions like the Maillard reaction, which creates complex flavor compounds. You can measure moisture content using advanced tools like Raman spectroscopy or thermogravimetric analyzers, which provide precise readings between 100°C and 200°C.

The packaging you choose plays an important role in moisture control. You'll want materials that maintain ideal moisture levels while preventing unwanted moisture absorption or loss. Regular monitoring using automated analytical tools helps you stay within industry standards and guarantees your ash-aged foods develop the intended flavor profiles without compromising quality or safety.

Traditional Preservation Meets Modern Science

Bridging ancient wisdom with cutting-edge technology, ash-based food preservation has evolved into a sophisticated blend of traditional methods and modern scientific approaches.

You'll find that today's food scientists are integrating wood ash's natural properties with advanced preservation techniques like nanoencapsulation and bio-preservation. This combination maximizes both the traditional benefits of ash and modern scientific innovations.

The integration of ash preservation with modern methods has led to enhanced food safety and longer shelf life. You can now find ash-based preservation techniques working alongside hurdle technology, creating multiple barriers against food spoilage while maintaining the unique flavors that ash aging provides.

- Nanoencapsulation protects the beneficial compounds in ash while ensuring controlled release of its preservative properties.

- Smart packaging systems monitor moisture levels when using ash-based preservation methods.

- Bio-preservation techniques complement ash's natural antimicrobial properties.

- Advanced monitoring systems help maintain ideal conditions for ash-aged foods.

When you're preserving food with ash today, you're not just using an ancient technique – you're participating in a scientifically validated process that combines centuries-old wisdom with modern food safety standards and technological advances.

Ash Types and Their Effects

Ranging from traditional vegetable ash to modern activated charcoal, different ash types create distinct effects in food preservation and flavor development. You'll find that vegetable ash, derived from burning grapevines or wood, provides an odorless, tasteless medium that's essential for rind formation without adding unwanted texture.

| Ash Type | Key Properties | Primary Effects |

|---|---|---|

| Vegetable Ash | Fine, sterile powder | Aids rind formation |

| Activated Charcoal | Enhanced micropores | Increases absorption |

| Traditional Ash | Alkaline nature | Raises surface pH |

| Food-Grade Ash | Standardized quality | Controls ripening |

| Historical Ash | Region-specific | Protects from contaminants |

When you're working with activated charcoal, you'll notice it's particularly effective at neutralizing surface acidity and managing moisture levels. This specialized form of ash contains finer micropores that enhance its absorption capacity, making it ideal for developing specific molds like P. candidum.

The alkalinity of these ashes plays an essential role in creating the perfect environment for beneficial microbes. You'll see this effect particularly in acid-set cheeses, where the ash helps counteract acidity and modulates the ripening process, ultimately contributing to the development of complex flavor profiles.

Ripening Process Enhancement

You'll find that ash plays an essential role in accelerating microbial growth during cheese ripening by creating an ideal surface pH balance.

The ash's alkaline properties work actively with salt to neutralize surface acidity, promoting the development of beneficial molds and yeasts that enhance flavor complexity.

Through its moisture control mechanisms, ash helps maintain optimal surface conditions by absorbing excess moisture while allowing the cheese to dry evenly during aging.

Microbial Growth Acceleration

Accelerating the ripening process through microbial growth has revolutionized how we control food maturation. You'll find that engineered bacteria, particularly modified E. coli strains containing the ethylene-forming enzyme from Pseudomonas syringae, can precisely control ripening speeds. These bacteria produce ethylene, which triggers essential chemical reactions that break down starches and acids into simpler sugars.

When you're working with microbial ripening, temperature plays an important role in the process. Higher temperatures activate the enzymes responsible for breaking down complex compounds, while cooler environments slow this activity. You'll notice that enzymatic activity becomes more pronounced as temperatures rise, leading to faster ripening and softening of fruits.

- Engineered bacteria can be regulated using arabinose and blue light systems to control ethylene production

- Ethylene-producing microbes break down chlorophyll in citrus fruits, changing their color

- Hydrolytic enzymes increase their activity at higher temperatures, accelerating the softening process

- Regular revitalization of bacterial cultures maintains consistent ethylene production levels

The effectiveness of microbial ripening can be measured through iodine assays for starch degradation and tensile strength tests that demonstrate fruit softening rates.

Surface Ph Balance

Surface pH balance plays an important role in controlling the ripening process and flavor development of aged foods. When you're aging food in ash, the pH level directly influences how chemical reactions occur on the food's surface, affecting both flavor development and texture preservation. The right pH balance guarantees that enzymes function effectively while preventing unwanted degradation of the food's surface.

You'll find that pH levels can either speed up or slow down the chemical reactions that create new flavors. During the aging process, the interaction between pH and microbial activity leads to the breakdown of proteins and fats, resulting in unique flavor compounds. For instance, when you're aging cheese, maintaining a pH around 5.4 is vital for achieving the desired taste and consistency.

The surface pH also protects your food's integrity. If the pH isn't properly balanced, you'll risk damaging the food's surface, which can lead to altered flavors and compromised texture.

It's important to maintain the correct pH range specific to each food type, as this guarantees proper flavor development while preventing the growth of harmful microorganisms that could spoil your aged foods.

Moisture Control Mechanisms

Effective moisture control mechanisms serve as the cornerstone of successful ash-aging and ripening processes. You'll find that industrial humidifiers and controlled atmosphere systems work together to maintain ideal humidity levels, ensuring your foods develop their desired flavors uniformly.

These systems can lower ambient temperatures by up to 20 degrees Fahrenheit while preventing spoilage from airborne bacteria.

When you're managing the ripening process, automated systems and precision technologies help you control multiple variables simultaneously. You'll achieve better results by using sensors that monitor and adjust humidity levels, ethylene concentration, and gas composition in real-time.

These controls create the perfect environment for flavor development while extending shelf life and reducing waste.

- Automated humidifiers maintain consistent moisture levels while conserving energy and water through precise droplet control

- Modified Atmosphere Packaging (MAP) enhances gas mixtures to preserve freshness and enhance flavor development

- Controlled atmosphere systems adjust oxygen, carbon dioxide, and nitrogen levels to manage ripening speed

- Precision ripening technologies trigger flavor development at ideal times through careful ethylene management

Through these moisture control mechanisms, you'll maximize the quality of your ash-aged products while minimizing resource consumption and maintenance requirements.

Flavor Compounds Through Time

Over time, flavor compounds in ash-aged foods undergo complex transformations through various chemical reactions and microbial activities.

You'll find that heat from ash aging triggers essential processes like the Maillard reaction, where amino acids interact with reducing sugars to create new flavor profiles. The high temperatures can also caramelize sugars, adding depth to the overall taste.

When you're aging foods in ash, microorganisms play a key role in developing unique flavors. These tiny organisms produce compounds like lactic acid and ethanol through fermentation, which contribute to the food's distinct taste. The process is similar to what you'd find in cheese or yogurt production, where controlled microbial activity enhances flavor without causing spoilage.

You'll notice that pH levels and moisture content greatly influence how these flavors develop. The balance between water and ash content affects both chemical reactions and microbial activity.

During the aging process, cooking conditions matter too – the concentration of flavors intensifies as liquids evaporate, while specific techniques like smoking or charring introduce additional flavor compounds that contribute to the food's complex taste profile.

Environmental Control Through Ash

Ash management demands careful consideration when controlling environmental impacts, particularly in food production and agricultural settings.

You'll need to understand that while ash can enrich soil with basic cations, its potential toxicity requires strict monitoring and control measures. When you're working with ash in food-related environments, you must guarantee that any residues don't contain harmful levels of dioxins or furans that could contaminate the food chain.

- Controlled recycling through pelletizing can make ash safer for agricultural use by reducing heavy metal content below regulatory limits.

- Basic cation enrichment from properly processed ash can benefit soil quality without the risks associated with raw ash disposal.

- Strict monitoring of POPs levels is essential to prevent contamination of food products and agricultural land.

- Different soil types respond differently to ash application, with peaty soils showing more positive results.

You'll find that proper environmental control involves careful testing and implementation of safety measures.

While ash can contribute to flavor development in certain foods, you must prioritize safety through regulated handling procedures and appropriate processing techniques. This guarantees that any ash-related food production methods don't compromise environmental or human health standards.

Texture Changes During Aging

You'll notice significant changes in texture as ash-aged foods progress through time, with moisture levels gradually shifting under the ash's absorption properties.

The surface of your cheese will develop a firmer texture as the ash draws moisture outward while maintaining proper internal consistency.

This controlled hardening process, guided by the ash's drying effects, helps you achieve the ideal texture balance between the rind and the interior of the cheese.

Moisture Control Through Time

Throughout the aging process, moisture content plays a critical role in determining how food textures evolve and develop. You'll find that controlling moisture levels during aging isn't just about preservation – it's essential for developing the right flavors and ensuring food safety.

When you're aging food, maintaining ideal moisture content helps prevent unwanted microbial growth while allowing desired chemical reactions to occur. The relationship between moisture and aging is particularly complex, as you'll need to balance preservation with texture development.

Water activity directly impacts how your food ages, influencing both chemical reactions and microbial interactions that create unique flavor profiles.

- Low moisture content in dry-aged foods helps concentrate flavors while preventing harmful bacterial growth

- Moisture migration during aging can affect the food's structural integrity and final texture

- You'll need to monitor humidity levels carefully to prevent both over-drying and excessive moisture absorption

- Proper packaging selection based on moisture content helps maintain perfect aging conditions

Surface Hardening Process

The physical transformation of food during aging extends beyond moisture control to encompass significant textural changes. As you examine aged foods, you'll notice that aging processes directly affect their surface texture and internal structure through complex enzymatic activities and protein breakdown.

During aging, you'll find that enzymes actively break down connective tissues and proteins, leading to notable changes in the food's texture. When you're dealing with meat specifically, these enzymatic activities transform tough cuts into more tender ones. You're fundamentally witnessing a natural tenderizing process where proteins gradually degrade, creating a more pleasant eating experience.

You'll observe that different aging methods produce varying textural results. If you're using dry aging, you'll notice more moisture loss, which concentrates flavors but can create a firmer exterior. When you're wet aging, you'll maintain more moisture, resulting in a different texture profile.

The aging duration also plays a vital role – you'll need to carefully control the time to achieve your desired texture, as longer aging periods intensify these changes. Remember that maintaining consistent aging conditions is important for achieving uniform textural development throughout your food product.

Regional Ash Aging Methods

Regional ash aging techniques vary dramatically across cultures, from traditional European cheesemaking to Northern Ugandan cooking practices and Native American culinary traditions.

In European cheesemaking, you'll find carefully controlled ash applications that create ideal pH conditions for beneficial microbes like Geotrichum candidum. While modern producers often purchase standardized ash, traditional methods relied on kitchen hearth remnants.

Northern Uganda's approach focuses on crop ash filtrate, particularly from legumes and sesame. You'll notice it's primarily used to reduce cooking times and enhance flavors, though locals often prefer salt-based seasonings in blind taste tests.

Native American cuisine incorporates wood and plant ash, rich in calcium carbonate, for both cultural significance and practical culinary applications.

- Traditional European cheesemakers use ash to encourage specific microbial growth and adjust surface pH

- Modern commercial ash production has standardized the process, though regional variations persist

- Northern Ugandan methods demonstrate ash's ability to reduce cooking times by up to 18%

- Native American culinary traditions incorporate ash for both its mineral content and cultural significance

These regional variations highlight ash aging's versatility and its deep roots in global food culture, despite regulatory challenges like the FDA's 2014-2016 restrictions on ash-ripened cheeses.

Frequently Asked Questions

Can Ash-Treated Cheeses Be Consumed by People With Activated Charcoal Allergies?

Yes, you can safely eat ash-treated cheeses even if you're allergic to activated charcoal. The food-grade ash used in cheesemaking is different from medical-grade activated charcoal and doesn't cause allergic reactions.

How Does Ash Aging Affect the Nutritional Value of Different Foods?

You'll find that ash aging primarily affects food's mineral content and pH balance. It can enhance calcium absorption in cheeses and may influence protein preservation, though specific nutritional changes vary by food type.

What Safety Certifications Are Required for Commercial Ash-Aging of Foods?

You'll need FDA GRAS certification, cGMP compliance, and HACCP accreditation for commercial ash-aging. It's also essential to obtain ISO food safety certifications and maintain regular quality control documentation for your operations.

Does Ash Aging Impact the Shelf Life of Foods Differently at Various Temperatures?

You'll find ash aging works best at room and cool temperatures, where it substantially extends shelf life. It's less relevant for frozen foods, but it'll effectively preserve your food by creating a protective, moisture-free environment.

Can Home Cheesemakers Safely Replicate Traditional Ash-Aging Techniques Without Special Equipment?

You can safely replicate ash-aging at home using food-grade activated charcoal, basic kitchen tools, and a controlled environment. Keep temperatures around 50°F, maintain 85% humidity, and regularly flip your cheeses during aging.

In Summary

You'll find that ash aging transforms foods through multiple mechanisms working in harmony. As you explore this ancient technique, you'll see how ash creates an ideal environment by controlling pH, moisture, and microbial activity. While chemical reactions create new flavor compounds over time, the ash's mineral content and environmental control shape the final product's unique characteristics. It's a fascinating process that continues to intrigue both chefs and food scientists.

Leave a Reply