You'll discover seven remarkable ice house designs that shaped ancient food preservation. The Persian Yakhchāl's towering dome system utilized solar chimneys and windcatchers, while British underground chambers featured egg-shaped brick structures with clever ventilation. American deep storage pits maximized north-facing slopes, and Mesopotamian designs connected to qanats for enhanced cooling. Chinese mountain storage facilities boasted rammed earth walls, while Roman subterranean chambers showcased intricate tunnel networks. Medieval cylindrical ice towers rounded out these engineering marvels with their layered insulation systems. Exploring these innovative designs will reveal how ancient civilizations mastered the art of keeping things cool.

Persian Yakhchāl Dome System

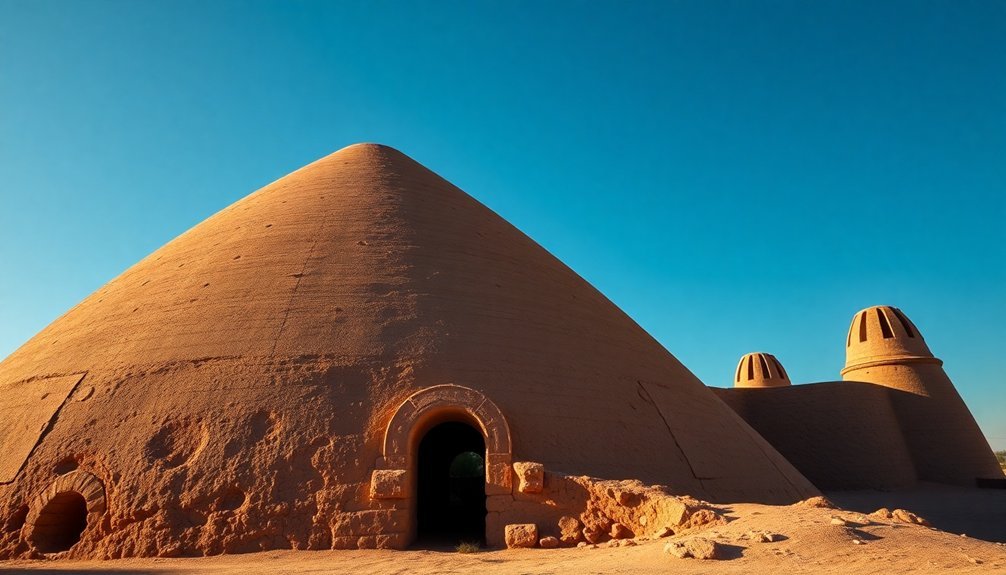

For over two millennia, Persian engineers have employed the remarkable yakhchāl dome system to produce and store ice in desert climates.

You'll recognize these structures by their distinctive conical or domed shapes, which rise up to 60 feet high and feature walls over two meters thick at the base.

The dome's construction relies on sarooj, a specialized waterproof mortar made from sand, clay, egg whites, lime, goat hair, and ash. This innovative material keeps water out while maintaining the structure's insulating properties. A special ceremony marked the sealing of the yakhchal door before summer storage began.

Below ground, you'll find vast storage spaces up to 5,000 m³ in volume where ice is stored in alternating layers with straw for insulation.

The system works through multiple cooling mechanisms. You've got the solar chimney effect drawing heat up and out through the dome's top, while windcatchers channel cool air downward.

At night, workers remove straw coverings to allow radiant cooling, and water from qanats runs along the northern walls for additional cooling.

When you need ice during summer months, you'll find it perfectly preserved in these underground chambers, ready for making traditional Persian desserts or preserving food.

British Underground Brick Chambers

While Persian yakhchāls dominated desert regions, British engineers developed their own ingenious ice storage solution: underground brick chambers.

These structures were built with thick brick walls, often lined with London Clay, and employed English bond brickwork for peak structural integrity. A prime example is the 9.5-meter deep ice well discovered at Park Crescent West.

You'll find these chambers constructed in egg-shaped or conical designs, carefully positioned between buildings or beneath soil mounds for prime insulation.

They'd include essential features like top ventilation holes and sophisticated drainage systems to manage inevitable meltwater.

The walls were typically coated with cement render in the upper sections, while the storage areas used hay, straw, or sawdust as insulating materials.

If you'd visited one in the 17th century, you'd have seen ice sourced from local ponds or imported from Norway being stored for wealthy landowners and food businesses.

King James I's ice house at Greenwich marked one of England's earliest examples.

Though these structures fell into disuse with the arrival of mechanical refrigeration, you can still find many preserved as Grade II listed buildings today.

Recent discoveries, like the Park Crescent West ice well in 2014, continue to reveal these remarkable feats of historical engineering.

American Deep Storage Pits

Across the Atlantic, American colonists adapted and enhanced European ice storage techniques with their own deep storage pits. You'll find these pits were typically excavated in an inverted cone shape, lined with stone, and featured angled walls that helped maintain ice as a solid mass during melting periods.

These innovative storage systems used carefully planned drainage, with gravel beds at the bottom to prevent water from contacting the stored ice. You'll notice their practical design incorporated wooden platforms made from common fence rails, keeping ice elevated above the drainage system. Similar to the early settler pits discovered at James Fort, these storage structures demonstrated colonial ingenuity in adapting to new environments.

| Feature | Purpose | Materials |

|---|---|---|

| Cone Shape | Dense ice packing | Stone lining |

| Drainage Base | Water removal | Gravel, rails |

| Wall Design | Heat reduction | Stone, straw |

| Cover Structure | Weather protection | Earth, wood |

When building these pits, you'd want to evaluate placement carefully. Most were situated on north-facing slopes, ensuring easy access while remaining protected from prevailing winds. The first American icehouse, built by Robert Morris in 1785, set standards that would influence designs until modern refrigeration made them obsolete. These structures could preserve ice from winter through October, thanks to their thick stone walls and extensive straw insulation.

Mesopotamian Ice House Architecture

You'll find that Mesopotamian ice houses featured sophisticated underground chambers carved deep into the earth, sharing similarities with the Persian yakhchāl's subterranean design.

The builders relied on locally sourced materials like clay, straw, and bitumen for insulation, creating thermal barriers that effectively maintained cool temperatures.

Their innovative drainage systems incorporated sloped channels and collection basins, which prevented meltwater from compromising the ice storage while allowing for its potential reuse.

Underground Construction Methods

Ancient Mesopotamian ice houses featured three key underground construction elements: deep storage chambers, intricate drainage systems, and strategic connections to qanats. You'll find these storage spaces extending up to 5000m³ below ground, where they'd maintain consistently cool temperatures for preserving ice and food throughout the year.

To construct these chambers, workers would excavate deep pits using the extracted mud and clay to form specialized bricks. They'd mix these building materials with a unique mortar called s?rooj, containing sand, clay, egg whites, lime, goat hair, and ash, making the walls water-impermeable.

You'll notice the walls are remarkably thick – up to two meters at the base – providing exceptional insulation.

The drainage system's design is particularly clever. You'll see trenches at the bottom of the storage space that catch melting water, allowing it to refreeze during cold nights.

The structure's connection to qanats (underground aqueducts) provides both water and cool air circulation. When combined with windcatchers, or bâdgirs, this system creates a natural cooling mechanism that draws cool subterranean air through the structure, maintaining ideal preservation temperatures.

Thermal Insulation Materials Used

Building upon these sophisticated underground structures, Mesopotamian ice houses employed a diverse range of insulation materials to maintain their cooling efficiency.

You'll find that ancient builders utilized natural fibers extensively, with tamarisk branches being a particularly effective choice in hot climates. They'd also incorporate straw mats and wood shavings strategically placed above and below the stored ice.

A remarkable innovation was the use of Sarooj mortar, which you'll recognize as a specialized blend of sand, goat hair, clay, egg whites, ash, and lime. This unique mixture didn't just provide insulation – it created a water-resistant barrier that protected the structure's integrity, especially in harsh desert conditions.

You'll notice how builders maximized the earth's natural cooling properties by digging deep pits, reducing the need for additional insulation.

They'd enhance this natural advantage with double partition designs, filling hollow spaces with non-conducting materials like wet tan or sawdust. The system was often completed with clever ventilation features, including lattice windows to manage warm air, while marble pieces allowed light penetration without compromising the cooling effect.

Drainage System Innovation

Throughout Mesopotamian ice house construction, drainage systems likely drew inspiration from the region's sophisticated water management practices, though direct historical records remain scarce.

You'll find that while specific ice house drainage designs aren't documented, the Mesopotamians' expertise in water management offers clues to their potential approaches.

The region's signature ring-drains and seepage-pits, commonly used for general waste management, could've been adapted for ice house drainage. You'd typically see vertical shafts lined with perforated pottery rings in their dwellings, suggesting similar techniques might've been applied to handle ice melt.

Looking at later Persian ice houses provides additional insights into possible Mesopotamian methods. These structures used shallow pools for ice formation and incorporated underground cooling systems.

You'll notice how they managed meltwater through natural shading and underground channels, a technique that might've evolved from earlier Mesopotamian practices.

The ventilation systems, including high domes and air vents, would've worked alongside any drainage setup. While you can't find explicit evidence of complex drainage systems, the combination of underground construction and plaster linings suggests they utilized practical solutions for managing ice melt.

Chinese Mountain Ice Storage

Deep within China's mountains and valleys, ice storage facilities emerged as sophisticated structures during the Spring and Autumn Period, reaching technical maturity by the Warring States era. You'll find these cellars were deeply buried with multiple channel doors and rammed earth walls, creating an impressive insulation system that kept temperatures constant.

When you examine these structures, you'll notice the innovative drainage solutions they employed. The floors were paved with square bricks leading to pottery well traps, while sandy schist bottoms enabled efficient water management. You'll see how they've protected the ice using straw and mud seals, along with the distinctive "Ice Jian" containers.

| Feature | Purpose | Design Element |

|---|---|---|

| Rammed Earth Walls | Temperature Control | Square Groove Bricks |

| Multiple Doors | Air Isolation | Channel System |

| Sandy Schist Bottom | Water Management | Pottery Drains |

| Straw Coverage | Heat Insulation | Mud Sealing |

| Ice Jian Container | Ice Preservation | Large Mouth, Small Bottom |

These facilities served multiple functions beyond basic storage – you could find them being used for sacrificial rites, summer meal preservation, and even body storage. The system was so effective that it continued to be used through the Ming and Qing Dynasties until modern refrigeration took over.

Roman Subterranean Cooling Chambers

While the Romans didn't construct dedicated ice houses, you'll find they mastered underground cooling through sophisticated architectural techniques integrated into their buildings.

You can see their expertise in waterproofing methods, where they pumped cool water from aqueducts through walls using lead pipes and sealed channels.

Though lacking direct evidence of specific subterranean cooling chambers, their layered approach combined thick insulating walls, natural ventilation, and underground spaces to maintain cooler temperatures in wealthy Roman homes.

Underground Construction Techniques

Ancient Roman engineers mastered the art of underground construction through their innovative use of local materials and sophisticated design techniques. They relied heavily on tufa and pumice, abundant volcanic rocks that were easy to carve yet provided remarkable stability for their subterranean structures.

You'll find these materials particularly prominent in their cooling chambers and storage areas.

The Romans' construction expertise is evident in their layered approach to underground building. They'd create intricate networks of corridors and tunnels that could extend several levels beneath the ground, connected by slender staircases.

To maintain proper temperature control and air circulation, they incorporated sophisticated ventilation systems with lattice windows and flues.

Here are four key engineering techniques that made Roman underground structures so effective:

- Double-partition walls filled with insulating materials to maintain stable temperatures

- Conical or rounded bottom designs with integrated drainage systems to manage water

- Gridded tunnel networks for efficient air circulation and temperature control

- Strategic placement of rooms relative to heat sources for ideal temperature gradients

These construction techniques proved so effective that they influenced architectural practices for centuries to come.

Waterproofing Methods

Roman engineers developed remarkably effective waterproofing methods for their subterranean cooling chambers, combining specialized materials with precise application techniques.

You'll find their methods particularly relevant when constructing an underground ice house, as they've stood the test of time for centuries.

To waterproof your ice house effectively, you'll want to start with a solid foundation using stone blocks, followed by a specialized mortar coating along the floors and walls.

The Romans' use of pozzolana-based concrete proves especially useful, as it creates an exceptional water-resistant barrier. You can apply this material in multiple layers to guarantee complete waterproofing.

For the walls, you'll need to incorporate a combination of tiles, bricks, and waterproof mortar.

Don't forget to construct vaulted roofs, which not only provide structural support but also prevent water infiltration from above.

The key to long-term success lies in including maintenance access points, similar to the Romans' putei system.

These access shafts will let you inspect and repair any water damage over time, while also allowing you to clear any mineral deposits that might compromise the waterproofing integrity of your ice house.

Layered Insulation Systems

Effective insulation proved essential to the success of Roman subterranean cooling chambers, employing multiple layers of specialized materials to maintain consistently low temperatures.

You'll find these historic structures utilized double partitions filled with non-conducting substances like wet tan or sawdust to create a robust thermal barrier. The insulation system extended from the floor to the roof, with careful attention to preventing heat infiltration at every level.

Key components of the layered insulation system included:

- Straw mats and sawdust covering the ice directly, protecting it from both sunlight and unwanted air circulation

- Double-walled partitions with hollow spaces filled with wet tan or sawdust, creating an effective thermal break

- Wood shavings and blocks at the floor level, allowing water drainage while maintaining insulation

- Ventilated spaces between the upper floor and roof, facilitating the escape of warm air

You'll notice the insulation wasn't limited to just one area – it wrapped around the entire structure.

The floor above the vault was covered with dry tan or sawdust, while wooden partitions inside the brick or stone walls provided additional thermal protection, creating a thorough insulation envelope.

Medieval Cylindrical Ice Towers

During the medieval period, cylindrical ice towers emerged as sophisticated architectural solutions for preserving ice year-round. You'll find these impressive structures were typically built partially or fully underground, featuring brick-lined walls that provided both structural integrity and temperature regulation. The cylindrical shape wasn't just for aesthetics – it played a vital role in the tower's functionality.

If you'd examined these towers closely, you'd notice their distinctive rounded bottoms, designed to collect and channel away any melted ice through a specialized drainage system. The walls incorporated thick layers of insulation, usually straw or sawdust, sandwiched between double partitions.

You'll find the construction materials were carefully selected, with specialized mortars like Sārooj being used in some regions for superior heat resistance.

The towers' ventilation system included lattice windows in the gables, ensuring proper airflow while maintaining cold temperatures. When you're storing ice blocks, you'd pack them against wooden partitions inside the brick walls, with additional insulation of dry tan or sawdust covering the floors.

This design became particularly popular among wealthy European households after 1660, influenced by Italian architectural innovations.

Frequently Asked Questions

How Did Workers Safely Stack Ice Blocks up to 80 Feet High?

You'll need skidding ramps, pike poles, and ice tongs to gradually stack the blocks. Work in tiers using horse-drawn pulleys, and pack sawdust between layers to prevent blocks from freezing together.

What Temperature Ranges Could These Historical Ice Houses Typically Maintain?

You'd find historical ice houses maintained temperatures between 32-40°F (0-4°C). Even in summer heat, they'd keep these ranges through insulation, underground positioning, and proper drainage systems that prevented ice melt.

How Long Did It Take to Construct Traditional Ice House Structures?

You'll need about 3 to 6 months to build a traditional ice house. The timeline depends on factors like design complexity, permit approvals, foundation work, insulation installation, and final structural touches.

Which Insulation Materials Proved Most Effective Across Different Climate Zones?

You'll find closed-cell foam most effective in cold zones 6-8, while radiant barriers work best in warm zones 1-3. For hard-to-reach areas, spray foam provides superior insulation across all climate zones.

How Many Workers Were Typically Needed to Operate Large Ice Houses?

You'd need roughly 20-30 workers to run a large ice house efficiently, including ice cutters, handlers, delivery staff, and managers. The exact number varied based on seasonal demands and service area size.

In Summary

You'll find these remarkable ice storage designs showcase humanity's incredible ingenuity in preserving ice before modern refrigeration. From Persia's towering yakhchāl domes to Rome's sophisticated cooling chambers, each system adapted perfectly to its local climate and needs. While today's technology has replaced these historical marvels, their architectural brilliance continues to inspire sustainable cooling solutions and reminds us of our ancestors' resourcefulness.

Leave a Reply