You'll need these 7 proven methods to keep bugs away while drying fish: Use HDPE netting combined with blue nylon mesh as a physical barrier, maintain temperatures around 30-35°C with proper airflow, apply traditional salt treatments using a 6% brine solution, incorporate natural repellents like turmeric and neem extracts, control humidity levels between 40-60%, utilize smoke protection techniques at 80-90°F, and implement bio-friendly pest management with beneficial insects. These strategies work together to create an effective defense system, and there's much more to discover about maximizing each method's potential for ideal results.

Physical Netting Solutions

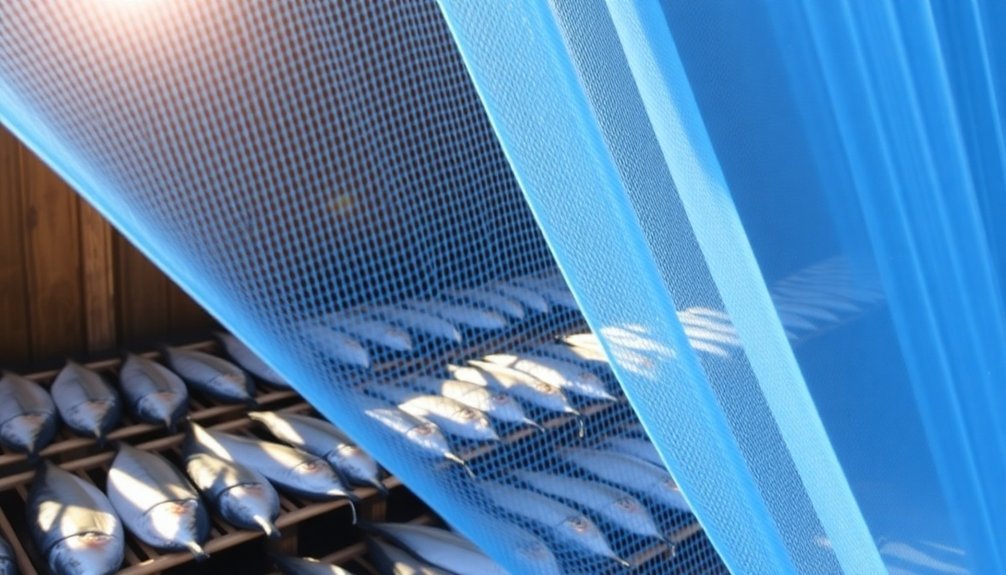

Through careful material selection, physical netting solutions offer effective protection for drying fish. High-density polyethylene (HDPE) netting combined with blue nylon mesh creates a durable and lightweight barrier that keeps insects away while maintaining proper airflow. You'll find this combination particularly effective at blocking mosquitoes and flies while allowing your fish to dry properly. Minimal upkeep is needed to maintain these nets at peak performance.

You can easily install these nets over your drying racks or frames, and they're flexible enough to cut and customize for your specific setup. The blue mesh guarantees you'll be able to monitor your fish throughout the drying process while maintaining consistent ventilation.

When you need to move your drying operation, you'll appreciate how portable these nets are. You won't need to worry about maintenance – simply clean the netting with mild soap and water when necessary.

The HDPE material's tear-resistant properties guarantee your investment will last, even in challenging outdoor conditions. Whether you're drying fish at home or in a commercial setting, you'll find these nets adapt well to various environments and configurations, providing reliable protection against insect contamination while promoting efficient drying.

Traditional Salt Treatment Methods

You'll need to start your salt treatment by preparing either a dry salt rub or a brine solution, with the brine method requiring 1 cup of salt per quart of water or 270g per liter for maximum effectiveness.

When using the dry method, you should apply approximately one-quarter of the fish's weight in salt, while for brining, you'll want to fully submerge your fish in the solution for 12-14 hours per 2kg of product. Coarse sea salt or kosher salt is recommended over table salt to avoid unwanted additives that can affect the final taste.

The salt concentration and soaking duration are essential factors that'll determine how well your fish resists insect infestation during the subsequent drying process.

Brine Soaking Techniques

Brining fish effectively requires understanding the delicate balance between salt concentration and soaking time.

You'll need to start by preparing your brine solution, which you can create by dissolving kosher salt in cold water – typically 5 tablespoons per 2 quarts. For enhanced flavor, you can add sugar and spices to your brine mixture.

You've got two main brining approaches to choose from. For quick results, use a 6% brine solution and soak your fish for up to 12 minutes. If you're not in a hurry, opt for a 5-12 hour soak in a 4.7% solution.

Make certain you've completely submerged the fish to guarantee even salt distribution throughout the flesh. Fish with lower oil content are ideal for this preservation method.

Once you've finished brining, you'll need to pat the fish thoroughly dry with paper towels.

For dry brining, season your fillet with salt and sugar, let it rest for 10 minutes, then rinse and dry again.

You can also use the traditional boiled seawater method, cooking it until salt crystals form, but remember to discard the final bit of liquid to avoid bitter salts like calcium chloride contaminating your brine.

Salt Quantity Guidelines

Three key factors determine the right salt quantity for traditional fish preservation: concentration, application method, and fish characteristics. You'll need to maintain a salt concentration of 6-10% in fish tissue to effectively prevent spoilage bacteria growth. This ideal range, combined with moisture reduction, creates an environment where harmful microorganisms can't thrive.

When deciding on salt quantities, consider these essential guidelines:

- Use a mixture of large and small grain sizes for dry salting to guarantee uniform distribution and prevent salt burn.

- Choose vacuum-processed or refined salt over solar or mine salt to avoid impurities that can affect penetration.

- Apply enough salt to achieve proper concentration while avoiding excess that could harm texture and taste.

If you're using dry salting, you'll want to carefully control the amount and contact time. For wet salting, maintain consistent concentration through regular stirring.

Remember that different fish species may require slight adjustments to salt quantities. Don't use salt containing high levels of magnesium or calcium, as these impurities can cause bitter flavors and reduce penetration rates, potentially leading to spoilage.

Natural Plant Based Repellents

Natural plant-based repellents consistently prove effective in protecting drying fish from unwanted insects. You'll find turmeric and neem particularly useful, with turmeric working best at 3% extract or 1.5% powder concentration, while neem requires a 5% extract or 1.5% powder concentration. You can apply these directly to your drying fish to maintain long-term repellency.

Essential oils offer another powerful defense against insects. Consider using citronella, lemongrass, or lemon balm, which all contain natural compounds that bugs hate. Bay leaves work especially well against weevils and cockroaches, while catnip's essential oils prove highly effective against various insects.

You can also incorporate garden herbs into your fish-drying process. Basil, chives, and rosemary not only add aromatic properties but actively repel different types of insects.

For ideal results, you'll want to combine these natural repellents with proper storage techniques. When you treat your dry fish with these plant-based solutions, you'll notice better sensory attributes and considerably fewer insects after months of storage compared to untreated fish.

Environmental Control Strategies

You'll find that controlling your drying environment is critical for keeping insects away from fish during the drying process.

By optimizing airflow with elevated racks and mechanical ventilation, while maintaining proper temperature levels between 30-35°C, you can create conditions that discourage pest activity.

Managing humidity through dehumidifiers or solar dryers will further protect your fish by speeding up the drying process and minimizing the time insects have to infest your product.

Optimize Drying Area Airflow

Maintaining ideal airflow in your fish drying area serves as a critical defense against bug infestations while guaranteeing efficient drying times. You'll need to achieve an air velocity of at least 3 m/s while keeping relative humidity below 60% to create an environment that's inhospitable to insects and advantageous for drying.

To maximize airflow effectiveness, consider these key strategies:

- Install mechanical or solar dryers with enclosed structures to control air circulation while protecting fish from bugs.

- Set up strategically placed fans and ventilation systems to increase air velocity throughout the drying area.

- Use mosquito netting or mesh screens that balance pest protection with sufficient airflow.

Position your drying racks with adequate spacing between fish pieces to guarantee uniform air circulation.

If you're using physical barriers like screens or netting, make sure they don't restrict the airflow too much.

You can enhance your setup by incorporating advanced climate control systems that automatically adjust temperature, humidity, and airflow.

For optimal results, consider using contraflow heat exchangers or ice water systems to manage moisture levels efficiently while maintaining strong air movement throughout your drying space.

Temperature Control Best Practices

Controlling temperature precisely during fish drying plays a significant role in preserving quality and preventing bug infestations. You'll want to maintain a steady temperature of around 30℃, as this creates an environment that's less attractive to insects while preserving the fish's nutritional value, color, and taste.

Don't rush the drying process by using high temperatures, as this can damage the fish's quality and create conditions that might attract pests. Instead, opt for low to middle temperatures and extend the drying time.

You'll need to monitor the temperature continuously using automated control systems that can adjust settings throughout different drying periods.

To maximize temperature control effectiveness, you should remove scales and viscera before drying, as this promotes even heat distribution. Make sure you're using equipment with proper thermal insulation materials and heat pump heating systems – they're more energy-efficient and provide consistent results.

While mechanical dryers require more energy than solar options, they'll give you better control over the drying environment and allow for 24-hour operation regardless of weather conditions.

Keep your drying area clean and elevated to prevent contamination, and use ice for cooling before starting the drying process.

Humidity Management During Drying

Along with precise temperature control, proper humidity management stands as a major factor in successful fish drying operations.

You'll need to maintain relative humidity between 40-60% to inhibit microbial growth and prevent moisture-related issues that can compromise your product's quality and safety.

For effective humidity control during the drying process, you'll want to focus on these critical points:

- Use dehumidifiers to remove excess moisture from the air, reducing condensation and preventing ice buildup that can slow down your drying process.

- Position your drying racks to maximize airflow and minimize exposure to ground moisture, guaranteeing faster and more uniform drying.

- Monitor water activity levels, aiming for 0.85 or below to achieve a shelf-stable product that meets food safety standards.

You'll find that proper humidity management prevents case hardening, where the fish's surface dries faster than its interior.

To maintain ideal conditions, verify your facility's dry air circulation reaches the ceiling to minimize water vapor.

When using mechanical dryers, recirculate the air to maintain consistent humidity levels throughout the drying process.

This approach helps you meet HACCP standards while protecting your product from harmful pathogens like Staphylococcus aureus.

Smoke Protection Techniques

Effective smoke protection techniques play an important role in keeping bugs away during the fish drying process.

You'll want to preheat your smokehouse and verify it's running on electricity or gas for better smoke quality control. If you're using wood, pre-burn your logs to minimize dense smoke that might attract unwanted insects.

You should maintain ideal smoking temperatures, keeping them around 80-90°F for cold smoking. Don't let your smoker produce excessive smoke during the initial hours, as this can create an environment that attracts bugs.

It's vital to keep your smoker clean and regularly disinfect the rods to prevent pest presence.

When applying smoke, make sure your fish surface feels tacky to touch – this prevents both bugs and undesirable smoke particles from sticking.

You'll need to carefully manage your smoking cycle to avoid curd formation and "exploded" pieces that can attract insects. During the process, maintain proper ventilation and airflow while keeping humidity levels below 75%.

Monitor the internal temperature of your fish, aiming for 160°F during hot smoking, and verify proper refrigeration afterward to maintain a bug-free product.

Bio Friendly Pest Management

While smoke protection offers one layer of defense, bio-friendly pest management provides a sustainable approach to safeguarding your drying fish.

You'll find nature's own pest control warriors highly effective, with ladybugs and lacewings ready to tackle common pests like aphids and whiteflies. For thorough protection, introduce predatory mites and beneficial nematodes to control both airborne and soil-dwelling threats.

Natural sprays and essential oils offer another eco-friendly defense line. You can create effective pest deterrents by mixing:

- Soap spray solutions for immediate control of soft-bodied insects

- Neem oil applications for broader pest management

- Lemongrass or peppermint oil sprays to repel flying insects

Don't forget to implement preventive measures alongside these bio-friendly solutions. Regular monitoring of your drying area helps you spot potential issues early, while maintaining proper ventilation reduces the likelihood of pest infestations.

You can enhance protection by combining physical barriers with aromatic plants like catnip or American Beautyberry around your drying station. These plants naturally repel many common pests and complement your other bio-friendly control methods.

Safe Chemical Applications

Safety stands paramount when considering chemical applications in fish drying. You'll need to understand that while chemicals like DDT and heptachlor are effective against insects, they pose serious health risks when misused.

It's essential to stay within the maximum recommended limits: 50 ppb for DDT and 10 ppb for heptachlor, endrin, aldrin, and dieldrin.

Before applying any chemicals, you should dip your fish in a 2-5% salt solution as a preliminary treatment.

When you must use chemical preservatives, strictly follow the manufacturer's instructions and dosage recommendations. Don't exceed the recommended amounts, as this can lead to pesticide resistance and increased health hazards.

You'll want to keep detailed records of all chemical applications and regularly test your products for residue levels.

If you're unsure about proper application methods, seek training from qualified professionals.

Remember that many traditional pesticides are now banned, so you'll need to verify that your chosen chemicals are legal and approved for use.

Consider implementing HACCP principles in your processing to maintain consistent safety standards and minimize the risk of chemical contamination.

Frequently Asked Questions

How Long Can Dried Fish Remain Insect-Free When Using Barrier Methods?

You'll find that dried fish can remain insect-free for several months when you use HDPE packaging and store it in cool, dry conditions. Regular inspections and proper maintenance of these barriers are essential.

What Temperature Conditions Are Most Effective for Preventing Insect Infestations?

You'll effectively prevent insect infestations by maintaining temperatures above 40°C during drying. For best results, aim for 50-65°C, as insects can't survive more than 5 minutes at 50°C or higher temperatures.

Can Combining Multiple Insect Control Methods Increase Effectiveness?

Yes, you'll get better results by combining methods like insecticides, salting, and environmental controls. When you integrate multiple approaches, you'll target different aspects of pest control and create stronger barriers against infestations.

Which Insects Are Most Commonly Found Damaging Dried Fish Products?

You'll find Cleridae and Dermestidae families most frequently damaging dried fish, with Cleridae making up 67.76% of pests. Specific species include Dermestes maculatus, D. frischii, D. ater, and Necrobia rufipes.

How Often Should Protective Barriers Be Replaced for Optimal Insect Control?

You'll need to replace your protective barriers every 6-12 months, depending on wear and tear. Check regularly for holes or damage, and replace immediately if you notice any compromised areas in the netting.

In Summary

You've now learned effective ways to protect your drying fish from insect infestations. Whether you're using physical barriers, natural repellents, or controlled smoking methods, you'll find these techniques both practical and cost-effective. Don't hesitate to combine different approaches for maximum protection. Remember, keeping bugs away isn't just about preserving your catch – it's about ensuring food safety and maintaining quality.

Leave a Reply