The top three mesh screen drying racks prioritize durability and efficient airflow. First, you'll find the heavy-duty galvanized steel wire models with powder-coated shelves, offering up to 50 adjustable layers for maximum drying space. Second, there's the space-saving design with lockable casters that compacts to 35% of traditional rack volume when not in use. Third, you'll want to take into account the multi-fan system racks with built-in humidity control and temperature monitoring. Each option provides versatile configurations for drying everything from small herbs to larger produce. Understanding their key features will help you make the most of your food preservation journey.

Basic Frame Assembly

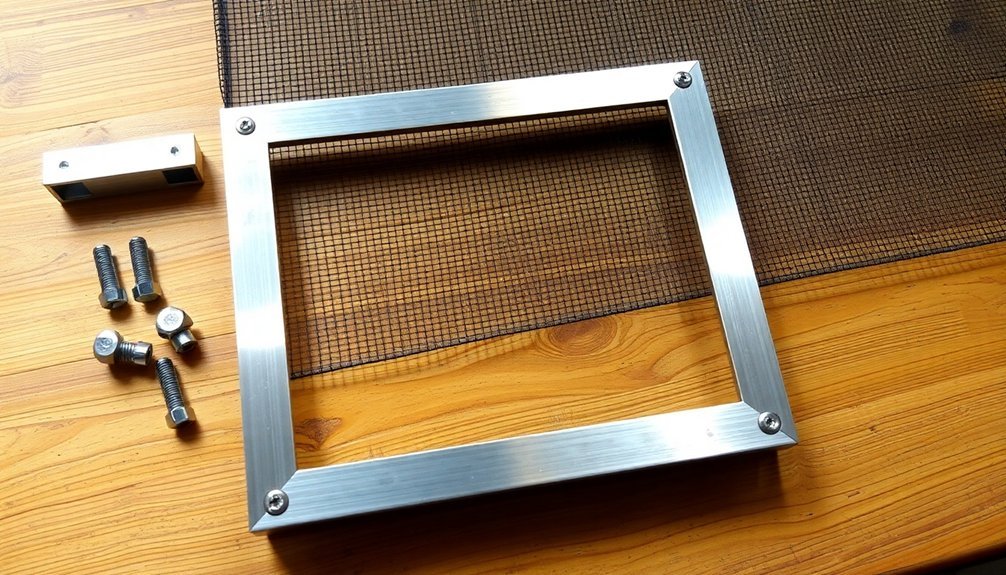

Building a mesh screen drying rack starts with gathering the essential materials and assembling a sturdy frame. You'll need furring strips, which are 1-by-2-inch wooden pieces that form the foundation of your drying rack, along with 1.75-inch and 2.5-inch drywall screws to secure everything in place. An electric drill and a staple gun are vital tools for this project.

To construct the frame, you'll begin by cutting the furring strips to your desired lengths using either a handsaw or an electric saw. Position the longer strips on their narrow edge, then fit the shorter strips between them to create a rectangular shape. Having proper air circulation between frames is essential for even drying of herbs and other foods.

When you're ready to connect the pieces, secure the corners using the 1.75-inch screws. It's important to create opposing joints at the corners for added stability and support.

You'll need to build two identical frames, as they'll eventually sandwich the mesh material between them. Make sure each frame is square and level before moving on to the next step.

The sturdiness of these frames is vital, as they'll support the weight of your food items during the drying process.

Multi-Layer Screen Configuration

A well-designed multi-layer screen configuration transforms your drying rack into a space-efficient powerhouse. You'll be able to adjust the spacing between layers from 1-2 inches up to 5 cm, letting you accommodate various food heights and types. The export fumigation-free wooden case packaging ensures safe delivery and handling.

The galvanized steel wire mesh and powder-coated shelves guarantee your food stays safe while providing excellent durability and corrosion resistance.

You can customize your rack's configuration to match your specific needs, whether you're drying small herbs or larger produce. The ability to convert from 50 layers to 25 layers gives you flexibility in your drying setup. Heavy-duty casters make it easy to move your loaded rack, while lockable wheels keep it secure during use.

Here's what makes these multi-layer configurations particularly effective:

- Adjustable layer spacing with removable shelves for different product heights

- Durable galvanized steel construction with engineering plastic components for stability and noise reduction

- Space-saving design that can be compacted to 35% of traditional rack volume for storage

The tilted supports and backstops prevent food from sliding, while rubber spacers protect your dried goods and minimize noise during movement.

Optimizing Airflow Placement

Strategic airflow placement makes or breaks your food drying success. You'll want to position multiple fans to create a continuous air cycle, with upward-facing units directing air through an empty top compartment. This design guarantees the air flows across your screen racks before cycling back down, preventing any stagnant spots that could compromise drying quality. Installing slats or racks helps maximize your available drying space while maintaining proper airflow.

To maximize efficiency, you'll need to install frequency converters (VFDs) on your fans. These automatically adjust to changes in resistance caused by different bed depths or screen placements. Start with maximum air volume and adjust as needed. Position your fans to blow directly across the screen racks, guaranteeing consistent coverage of your food items.

For ideal results, maintain a temperature between 75°-80°F and keep humidity below 30%. You'll want to install a filter in the door and an exhaust fan at the back to draw fresh air in while removing moisture-saturated air.

Don't forget to properly insulate your exhaust ducting to prevent condensation issues. Add weatherstripping to your door frame to maintain these perfect conditions. Monitor humidity and temperature levels with a hygrometer, and consider adding a dehumidifier if you're struggling to maintain low moisture levels.

Frequently Asked Questions

How Long Do Mesh Screens Typically Last Before Needing Replacement?

You'll find that mesh screens last 7-10 years if they're premium quality and well-maintained, while lower-quality screens typically need replacement after 3-5 years. Regular cleaning and proper installation extend their lifespan considerably.

Can These Racks Be Safely Used in Commercial Dishwashers?

You shouldn't put mesh screens in commercial dishwashers. They're typically not designed for high-temperature commercial washing. Instead, you'll want to hand wash them with mild soap to preserve their integrity and extend their lifespan.

What's the Maximum Weight Capacity per Mesh Screen Layer?

You'll want to limit each mesh screen layer to 3-5 pounds to prevent sagging and maintain proper airflow. For safety, distribute items evenly and consider using additional support if you're drying heavier foods.

Are There Specific Cleaning Solutions Recommended for Sanitizing Mesh Screens?

You'll want to use warm water and mild dish soap for general cleaning. For sanitizing, diluted vinegar or food-grade sanitizing solutions work well. Avoid harsh chemicals that could leave residue on your mesh screens.

Do Temperature Fluctuations Affect the Mesh Material's Food-Safe Properties?

You'll find that PTFE and FoodSAFE® mesh maintain their food-safe properties across temperature changes. However, you should avoid using polypropylene in extreme cold, as it may crack and compromise food safety.

In Summary

You'll get the most value from your mesh screen drying rack by following proper assembly, layering techniques, and airflow optimization. Whether you're dehydrating fruits, herbs, or making jerky, these three top-rated racks will serve your needs well. Remember to clean your screens thoroughly between uses and store them in a dry place to prevent mold and extend their lifespan.

Leave a Reply