Building your own wooden smokehouse is worth the effort for several compelling reasons. You'll get superior food preservation capabilities that can keep meats, fish, and cheese safely stored for months. Traditional smoking methods preserve essential nutrients better than high-heat cooking while creating unique, rich flavor profiles through various wood choices. You'll save money over time compared to store-bought units, and proper construction with quality materials like cedar or pine guarantees years of reliable service. With correct temperature control and proper ventilation, you're investing in a time-tested preservation method that offers benefits you'll discover as you explore traditional smoking techniques.

Benefits of Traditional Smoking Methods

Through the ages, traditional smoking methods have offered numerous advantages that modern cooking techniques simply can't match. When you smoke your food, you'll preserve more essential vitamins and minerals than you'd with high-heat cooking methods. The smoking process naturally renders out fat, making your meals notably healthier. The slow, indirect heat breaks down tough connective tissues while retaining the food's nutritional value, and you won't need to add extra fats, sugars, or salt to enhance flavor.

You'll discover that smoking isn't just about preservation – it's about creating exceptional taste experiences. You can experiment with different wood chips, tea leaves, and other materials to develop unique flavor profiles that suit your palate. The process naturally tenderizes meat while imparting rich, smoky notes that can't be replicated by other cooking methods.

Beyond the practical benefits, you'll find smoking to be a rewarding skill that connects you with historical traditions. It's a sustainable cooking method that relies on wood rather than modern fuels, and you'll appreciate the meditative aspects of tending to your smokehouse.

Plus, you're learning a valuable self-reliant skill while reducing food waste through extended preservation capabilities.

Essential Construction Materials

When building a smokehouse, selecting the right materials forms the foundation for a safe and effective smoking environment. You'll want to focus on using 1" x 6" tongue-and-groove pine or cedar boards for the walls, with cedar being particularly ideal for its natural weather resistance. Building a DIY smokehouse is achievable in one week with proper planning.

For the frame, 2" x 4" and 2" x 8" lumber provides sturdy support, but avoid pressure-treated wood as it can leach harmful chemicals into your food.

Your hardware choices are equally important. Opt for galvanized deck screws and hot-dipped galvanized nails for assembly, using varying lengths like 1 5/8" and 2 1/2" depending on the application.

For the roof, you'll need steel or metal roofing materials, being careful to avoid galvanized metal to prevent contamination.

- You'll see the tongue-and-groove boards fitting together seamlessly, creating tight, weather-resistant walls.

- You'll notice the sturdy frame taking shape as you connect the 2x4s and 2x8s with galvanized fasteners.

- You'll watch your smokehouse come together as you secure the metal roofing, complete with a ridge cap sealing the peak.

A proper smoke generation system rounds out your material needs, including a single burner system and hardwood chips for authentic flavor.

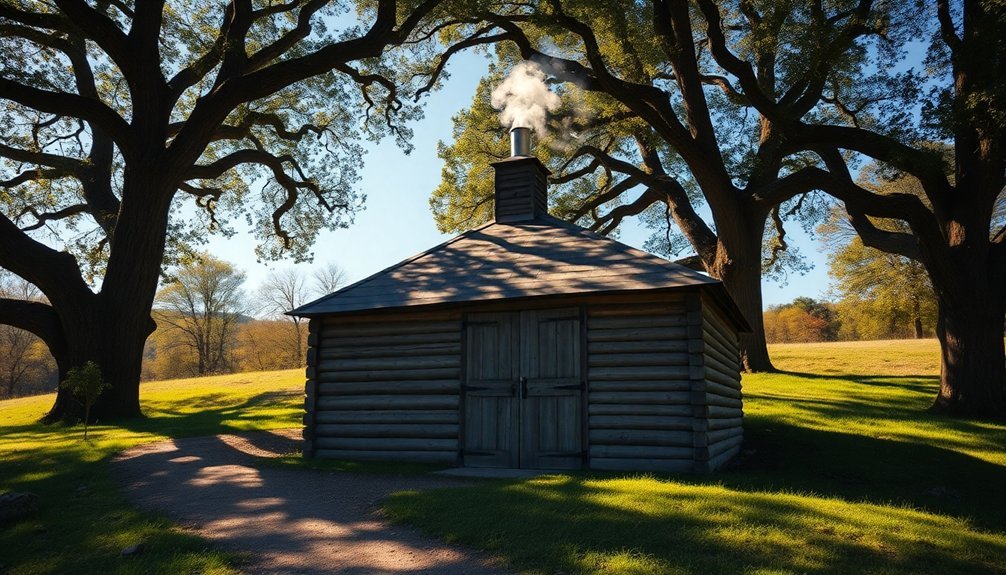

Choosing Your Smokehouse Location

When selecting your smokehouse location, you'll need a well-drained spot with stable ground to prevent water damage and maintain structural integrity.

Your chosen site should offer protection from harsh winds while allowing proper smoke ventilation, making a slightly elevated area ideal.

Keep your smokehouse at least 15 feet from other buildings and property lines, ensuring both safety and compliance with fire regulations. Consider consulting with your local zoning office before beginning construction to ensure your planned smokehouse meets all building permit requirements.

Drainage and Ground Stability

Before breaking ground on your smokehouse, proper site selection is essential for drainage and stability.

You'll want to choose a location on a slight slope or knoll, which naturally directs water away from your structure. The site should be at least 50 inches from other buildings and have well-draining soil to prevent water accumulation and structural issues.

Your foundation needs to extend below the frost line and incorporate concrete footings for both the smokehouse and firebox. Before construction, conduct soil tests to identify potential problems like poor soil quality or hidden boulders.

You'll need to guarantee the ground is perfectly level before laying your foundation materials.

- Install a proper floor drain that connects to a drainage system, managing both rainwater and smoking drippings.

- Create a stable base using layers of gravel, sand, and concrete to prevent shifting and improve drainage.

- Position the firebox at least 4 inches away from the main structure while maintaining easy access for maintenance.

Remember to verify that your chosen location complies with local zoning laws.

Protection From Elements

The success of your smokehouse largely depends on selecting a location that shields it from harsh environmental elements. You'll want to place your structure on elevated ground, preferably a knoll, to maximize ventilation and smoke movement. When choosing your spot, avoid areas with low-hanging trees that could create fire hazards or drop debris onto your smokehouse.

| Element Protection | Key Considerations |

|---|---|

| Fire Safety | Keep 50 inches from other structures |

| Ground Stability | Build foundation below frost line |

| Ventilation | Install noncombustible vents/flues |

| Structure Integrity | Use masonry or non-combustible walls |

| Weather Protection | Install metal doors with 1-inch overlap |

Your smokehouse's location shouldn't just consider current conditions but also long-term sustainability. You'll need to guarantee the foundation extends below the frost line, particularly in regions with severe weather. The concrete slab floor should be at least 3 1/2 inches thick, providing a stable base that resists moisture and temperature changes. When positioning your firebox, maintain a minimum 4-inch distance from the smokehouse, and set up the smoke channel at a 30-degree pitch for ideal smoke flow.

Distance From Buildings

In accordance with fire safety regulations, your smokehouse must maintain specific distances from existing structures on your property. You'll need to keep it at least 50 inches away from other buildings to prevent fire hazards, and many local codes require a minimum of 15 feet from property lines and other structures.

These distances aren't arbitrary – they guarantee proper ventilation and protect surrounding buildings from heat and smoke exposure.

When selecting your smokehouse location, think about three key placement factors:

- Position it on level ground or a slight slope, keeping it away from low-hanging tree branches that could catch fire or impede smoke flow.

- Place it where prevailing winds won't blow smoke toward your home or neighbors' properties, ideally on a knoll for ideal draft.

- Confirm the spot is easily accessible by foot and close to water sources, with stable soil conditions for a solid foundation.

Before finalizing your location, check local building permits and zoning regulations.

You'll need to comply with air quality standards and be ready for potential inspections.

Don't forget to take into account foot traffic patterns to prevent creating muddy areas around your smokehouse during frequent use.

Cost Savings Over Time

Building your own wooden smokehouse represents a smart long-term investment that can greatly reduce your smoking costs compared to store-bought units.

You'll save money through reduced maintenance needs, thanks to durable materials like heavy gauge steel and firebrick that last longer than cheaper alternatives.

The initial investment in quality materials and proper construction techniques pays off through efficient operation, using less fuel and requiring fewer repairs over time.

Long-Term Investment Returns

Making a significant investment in a wooden smokehouse can yield substantial financial returns over time. When you build your smokehouse using high-quality materials like pine and 2x4s, along with proper insulation and efficient design features, you're creating a long-lasting asset that'll pay for itself through years of reliable service and reduced operating costs.

Your investment returns will materialize through:

- Reduced fuel consumption due to efficient heat control systems and proper insulation, saving you money on wood, charcoal, or other fuel sources.

- Lower maintenance costs thanks to durable components like cast iron dampers and aluminum ducting that resist wear and tear.

- Decreased food expenses since you'll be able to smoke meats and other foods at home instead of buying expensive commercially smoked products.

You'll also benefit from the smokehouse's ability to maintain consistent temperatures and produce high-quality results, eliminating the need for re-smoking or wasting food.

The structure's durability means you won't need to replace it frequently, and its efficient design will continue to deliver cost savings throughout its extended lifespan, making it a worthwhile investment for any serious smoking enthusiast.

DIY Vs Store-Bought Comparison

When comparing DIY and store-bought smokehouses, you'll discover significant cost differences that impact your long-term savings.

With a DIY approach, you can drastically reduce expenses by using salvaged materials and buying lumber directly from sawmills, saving up to 90% compared to retail prices. You'll also have the flexibility to source free or low-cost alternatives like gravel and recycled wood, which adds character while keeping costs down.

Store-bought units require a substantial upfront investment, ranging from hundreds to thousands of dollars, plus potential additional costs for accessories and parts. While they offer immediate convenience and ready-to-use features, you're paying a premium for these benefits.

In contrast, your DIY smokehouse can be built gradually, allowing you to spread costs over time while customizing features to your specific needs.

Although a DIY project demands more time and effort initially, you'll benefit from lower maintenance costs and the ability to make improvements based on your experience.

You can achieve smoking results comparable to commercial units while maintaining control over materials, design, and functionality – all at a fraction of the cost of pre-made alternatives.

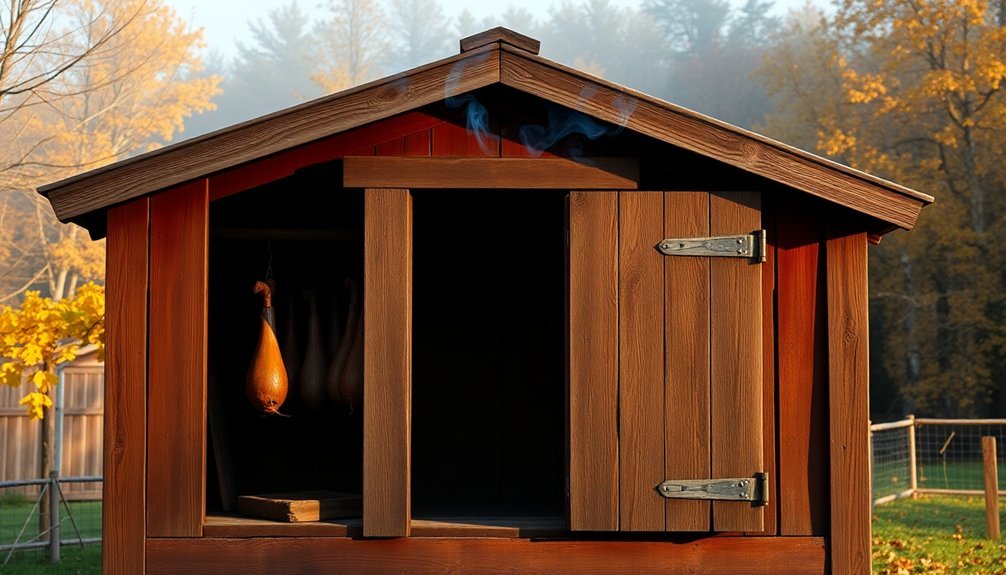

Meat Preservation Capabilities

A properly built smokehouse offers exceptional meat preservation capabilities through its dual-action curing and smoking process. You'll start by salt-curing your meat, which draws out moisture and begins the preservation process. This critical step requires repeated applications of coarse salt and rest periods, ensuring the salt penetrates deeply into the meat.

Once cured, your smokehouse maintains precise temperature control between 109-160°F, creating the ideal environment for long-term preservation. The hardwood smoke doesn't just add flavor; it actively reduces moisture content and eliminates harmful bacteria, making your meat safe for extended storage.

- Picture rows of hams and sausages hanging from sturdy racks, slowly taking on a rich mahogany color as smoke gently wafts around them.

- Imagine opening your smokehouse door to find perfectly preserved meats, ready for wrapping in cheesecloth and aging.

- Envision yourself slicing into perfectly preserved meat months later, knowing you've created a sustainable food storage solution.

After smoking, you'll need to chill the meat quickly and wrap it properly. With proper handling, your smoked meats can last several months to a year, providing you with a reliable food preservation method that's stood the test of time.

Flavor Enhancement Through Wood Selection

You'll discover that selecting the right wood for smoking is essential, as each variety imparts distinct flavors that can enhance your meats in unique ways.

For robust cuts like beef brisket, you'll want to start with oak or hickory as your base wood, while pork benefits from the sweeter profiles of apple or cherry wood.

If you're looking to create more complex flavor profiles, try combining woods such as hickory with cherry, or oak with apple, being careful to maintain a 70/30 ratio of base wood to accent wood.

Wood Pairing For Meats

Selecting the right wood for smoking meat can dramatically transform your barbecue results. You'll want to match the wood's intensity to your meat's robustness. For delicate meats like fish and poultry, stick to mild woods like apple, cherry, or peach.

Medium-intensity woods such as oak, hickory, and pecan work perfectly for pork and most beef cuts, while strong woods like mesquite and walnut are best reserved for robust meats like brisket and game.

For the best smoking results, consider these essential wood pairings:

- Poultry and fish – Use apple or cherry wood for a subtle, sweet flavor that won't overpower the meat's natural taste. Cedar planks work exceptionally well for salmon but avoid using cedar chips for smoking.

- Pork and ribs – Combine hickory as your base wood with a touch of apple or cherry for a perfect balance of smoky and sweet. Pecan adds a delightful nutty dimension.

- Beef brisket and game – Start with oak or hickory for a solid foundation, then add mesquite sparingly for an intense, earthy flavor. Post oak is particularly excellent for Texas-style barbecue.

Creating Complex Smoke Profiles

Creating complex smoke profiles goes beyond simple wood selection by combining different wood types throughout your smoking session. You can layer complementary woods to achieve depth and nuance in your smoked foods.

Start with a strong base wood like oak or hickory, which provides consistent heat and foundational smokiness, then add fruitwoods like cherry or apple to introduce subtle sweet notes.

You'll want to contemplate the burning characteristics of each wood type. Combine seasoned hardwoods that have 15-20% moisture content for the cleanest smoke.

Mix chunks with chips strategically – use chunks for sustained smoke production and add chips when you need quick bursts of specific flavors. For example, you might start with oak chunks for steady heat, add hickory for richness, then finish with cherry chips for a sweet undertone.

The timing of wood addition matters greatly. Begin with your base smoking wood, then introduce secondary woods during the middle of the cooking process.

You can create signature flavor profiles by experimenting with different wood combinations – try pairing mild alder with intense mesquite, or combine maple's subtle sweetness with hickory's robust character.

Safety and Food Protection

Safety stands as the cornerstone of any successful smokehouse operation, encompassing both structural integrity and food handling practices. You'll need to focus on fire prevention, structural requirements, and proper food handling to guarantee a safe smoking environment.

When building your smokehouse, make sure it's at least 15 feet from other structures and property lines, with a concrete foundation that's 3½ inches thick.

For peak fire safety and food protection, you should:

- Install a metal door that overlaps the opening by one inch on all sides, guaranteeing proper sealing and heat retention while maintaining structural integrity.

- Set up a dedicated food preparation area with separate utensils and cutting boards for raw and cooked meats to prevent cross-contamination.

- Keep a water source nearby and maintain constant supervision during smoking sessions.

Before starting construction, check with your local zoning office and obtain necessary permits.

You'll need to comply with local fire-resistant construction regulations and get recommendations from your fire department.

Remember, you can't sell meat from a home smokehouse, so keep your delicious creations for personal use only.

Always wash your hands thoroughly and avoid washing raw meat to prevent spreading bacteria.

Building Techniques and Design

The art of building a wooden smokehouse requires careful attention to both structural design and material selection. You'll want to use 1" x 6" tongue-and-groove pine or 1½-inch construction-grade lumber for the walls, while avoiding pressure-treated wood that could contaminate your food with chemicals when heated.

| Component | Material | Specification |

|---|---|---|

| Walls | Pine/Lumber | 1" x 6" or 1½" thick |

| Framing | Lumber | 2" x 8" or 2" x 6" |

| Fasteners | Screws | Galvanized deck/torque |

Your site selection is essential for proper smoke flow. Choose a well-drained location with a natural slope, positioning the firebox 8-10 feet from the smokehouse and 10-12 inches below the floor level. When assembling the structure, you'll need to set posts below the frost line and confirm your walls are square by measuring diagonal distances.

For proper ventilation, install a 6-inch concrete or 8-inch metal chimney pipe underground, extending it 3-4 inches above the floor. Don't forget to add vents covered with window screen at the peak to maintain proper draft. This design allows smoke to cool appropriately before reaching your food, especially important for cold smoking.

Long Term Value

Building your own wooden smokehouse pays off in numerous ways over time. You'll appreciate its ability to preserve meat for up to two years, markedly reducing your dependence on modern refrigeration. The combination of salt curing and prolonged smoking guarantees your food stays fresh while maintaining its quality, making it a reliable preservation method for generations.

The smokehouse's cost efficiency becomes evident as you'll save money by avoiding commercial preservation methods. Once built, it requires minimal maintenance while offering versatility in preserving various foods. You can smoke different types of meat, fish, and even cheese, adapting the structure to both cold and hot smoking processes.

- Picture yourself smoking a fresh-caught salmon, its flesh slowly taking on a rich golden hue as wisps of applewood smoke curl around it.

- Envision rows of carefully hung venison, the meat developing a deep mahogany color over weeks of careful smoking.

- Imagine sharing your traditionally smoked meats at family gatherings, passing down time-honored techniques and recipes.

The smokehouse also preserves cultural heritage, connecting you to ancestral methods while enhancing your self-reliance skills.

Environmental Impact

Four significant environmental concerns emerge when operating a wooden smokehouse: air pollution, climate impact, health risks, and environmental persistence.

When you're smoking foods, you're contributing to local air pollution through wood smoke, which releases more particulate matter than modern diesel engines. The smoke contains nitrogen oxides, VOCs, and particulates that form ground-level ozone and acid rain.

You'll be adding to the same pollution source that accounts for over 30% of particle pollution in areas like the San Francisco Bay during winter.

Your smokehouse operations will release CO2 that trees absorbed over years, and it'll emit more carbon dioxide than coal for the same energy output. The smoke contains black carbon, a potent climate pollutant, along with carcinogenic compounds like PAHs, dioxins, benzene, and formaldehyde.

These toxins don't just disappear – they persist in the environment, accumulating in soil, water, and the food chain.

If you're planning to use your smokehouse frequently, you'll need to take into account these environmental impacts. The toxins you release will contribute to both immediate air quality issues and long-term environmental degradation through their persistence in ecosystems.

Seasonal Usage Advantages

Throughout the year, a wooden smokehouse offers distinct seasonal advantages that maximize its utility and effectiveness. You'll find cold smoking particularly beneficial during the cooler months when temperatures naturally fall between 30-40°F, making it easier to maintain the vital sub-60°F smoking environment. This temperature control is essential for properly preserving meats while avoiding overheating issues.

Your smokehouse's versatility shines through its ability to handle both hot and cold smoking techniques. You can preserve large quantities of meat without worrying about freezer burn, and when properly cured, your smoked meats will retain their fundamental nutrients while developing rich, complex flavors.

- During fall, you can collect and dry various hardwoods, preparing your smoking materials for the season ahead.

- In winter months, you'll achieve ideal cold smoking conditions naturally, perfect for creating traditional hams and bacon.

- Throughout spring and summer, you can adapt your smokehouse for hot smoking techniques and experiment with smoking spices and nuts.

With proper planning and maintenance, you're able to use your smokehouse year-round, adjusting your smoking techniques and wood choices to match the seasons and your preservation needs.

Frequently Asked Questions

How Long Does It Take to Fully Cure Meats in a Wooden Smokehouse?

You'll need 1-3 weeks for proper meat curing, depending on the size and type. After curing, you'll smoke for 2 days: one day for drying and another for developing color and flavor.

Can Fish and Game Be Smoked Simultaneously in the Same Smokehouse?

You shouldn't smoke fish and game together as they require different temperatures and can cross-contaminate. If you must, use separate racks and maintain strict temperature control to guarantee proper smoking of both.

What Temperature Control Methods Work Best for Different Weather Conditions?

You'll need to adjust vents differently for hot and cold weather. In heat, close bottom vents to reduce airflow. In cold, open them wider. Always use water pans and insulation to stabilize temperatures.

How Often Should the Wood Smoking Chips Be Replaced During Operation?

You'll need to replace wood chips every 30-60 minutes during smoking. Watch for visible smoke – when it stops, it's time to add more. For overnight smokes, load up before bed and resume in the morning.

What Are the Best Cleaning Practices to Maintain Smokehouse Hygiene?

You'll need to clean your smokehouse after each use. Remove ashes, scrub grates, wipe down surfaces, and check for creosote buildup. Do a deep cleaning monthly by scraping walls and inspecting all components.

In Summary

Building your own wooden smokehouse proves worthwhile through significant cost savings on preserved meats, authentic flavors you can't replicate with modern methods, and the satisfaction of a practical DIY project. You'll appreciate the versatility across seasons and the sustainable approach to food preservation. When properly maintained, your smokehouse will serve as a valuable addition to your property for generations to come.

Leave a Reply