To master cheese aging, you'll need to control key environmental factors in your aging space. Start by maintaining temperatures between 45-58°F and humidity levels of 70-99%, depending on your cheese type. You should position your cheese cave on a north-facing wall or below grade for natural cooling, and guarantee proper insulation with materials like cement and lime wash. Begin with shorter-aging varieties like Muenster before advancing to complex cheeses like aged cheddar or parmesan. Remember to turn your cheeses regularly and monitor beneficial mold growth. The journey from novice to artisan awaits as you explore the intricate world of fine cheese aging.

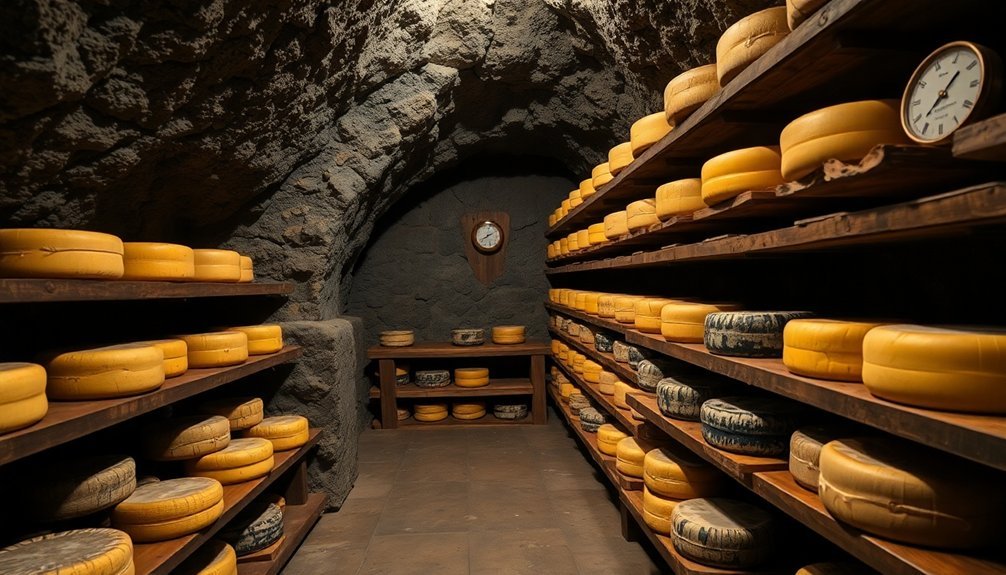

Fundamentals of Cheese Cave Design

Four key elements form the foundation of an effective cheese cave design: location, structure, ventilation, and insulation.

You'll want to position your cave on the north side of your building to minimize solar heat gain, and consider building below grade to take advantage of the earth's natural cooling properties.

Your cave's structure should incorporate rounded arch ceilings to promote air circulation, while walls and ceilings need thorough insulation to maintain stable conditions. Maintaining ideal cheese temperatures between 45-58°F is crucial for proper aging.

Use materials like cement and lime wash, which naturally regulate temperature and humidity. Install two-inch foam insulation and guarantee your doors are well-sealed with urethane-sandwiched plywood panels.

You'll need a reliable ventilation system with buried inlet pipes to pre-cool incoming air and outlet pipes for proper exhaust.

Filter and condition fresh air before it enters the cave to remove impurities. For smaller caves, regular door operation might provide sufficient air exchange.

Monitor your cave's environment consistently using hygrometers for humidity control.

You may need artificial heating and cooling units for seasonal adjustments, but consider energy-efficient options like chilled water circulating through stainless steel coils.

Essential Temperature and Humidity Control

With your cheese cave properly designed, mastering temperature and humidity control becomes your next major focus.

You'll need to maintain temperatures between 45°F and 60°F (7-15°C), with specific ranges depending on your cheese type. Soft cheeses thrive at 50-55°F, while hard cheeses prefer slightly warmer conditions at 55-60°F, and blue cheeses require cooler temperatures of 45-50°F. Relative humidity must stay between 70% to 99% at these temperatures.

Humidity control is equally vital, with most cheeses requiring 75-95% relative humidity. You'll want to keep soft cheeses at 90-95%, hard cheeses at 75-85%, and blue cheeses at up to 98%.

To achieve these conditions, you'll need reliable monitoring tools like digital hygrometer thermometers and temperature data loggers.

When conditions aren't ideal, you can make adjustments using specific tools. Install humidifiers or place water trays to increase moisture levels, and use dehumidifiers or increase air circulation when humidity's too high.

For temperature control, employ precision coolers, heaters, or modified wine fridges.

Remember that these conditions directly impact your cheese's flavor development, texture, and aging process – cooler temperatures create complex flavors while maintaining moisture, and proper humidity guarantees perfect rind formation and texture development.

Selecting Cheeses for Aging

Success in cheese aging begins with choosing the right varieties for your aging project. You'll want to focus on cheeses known for their aging potential, such as cheddar, gouda, parmesan, and Swiss cheese. These varieties develop more complex flavors and interesting textures over time. The aging process transforms the cheese through bacterial fermentation, which creates distinctive flavors and characteristics.

When selecting cheeses to age, consider the aging period you're willing to commit to. If you're new to aging, you might start with shorter-aging varieties like Muenster (5-7 weeks) or mild cheddar (2-3 months). For more ambitious projects, you can try parmesan, which requires 10-24 months to develop its characteristic sharp flavor.

You'll notice that different cheese types develop distinct textures during aging. Soft cheeses like Camembert remain smooth after just a few weeks, while semi-hard varieties like cheddar and gouda become firmer over 2-4 months.

For the most dramatic transformation, hard cheeses like parmesan develop a firm texture and form calcium lactate crystals, which contribute to their complex flavor profile.

Pay attention to the flavor developments you're seeking. You'll find nutty and fruity notes in aged parmesan, caramel-like flavors in aged gouda, and earthy notes in aged cheddar.

Proper Salt and Brine Methods

Salt and brine preparation stands as a cornerstone of proper cheese aging. To create an effective brine solution, you'll need to start with boiled water, adding 350-400g of salt per liter for a saturated solution or 70-80g for a lighter 7% aging brine.

Don't forget to incorporate calcium chloride (1/2 teaspoon per liter) once the solution has cooled to room temperature.

When you're aging your cheese, you'll need to maintain specific salt concentrations – typically 6-8% for soft white cheeses. The salt doesn't just enhance flavor; it controls moisture content and prevents unwanted bacterial growth while helping form a protective rind.

Store your brined cheese in an airtight container, making certain it's completely submerged using weights if necessary. You'll want to keep it at 8-12°C for softer cheeses or up to 18°C for harder varieties.

Remember to change your brine solution every 1-2 weeks if it's homemade, and always check for signs of spoilage. Different cheeses have varying brine storage durations – fresh mozzarella lasts about a week, while feta can age for several months.

Regular monitoring is vital to prevent mold growth and maintain proper aging.

Managing Beneficial Molds and Bacteria

To develop distinctive blue cheese cultures, you'll need to maintain precise temperature and humidity controls while ensuring proper air circulation throughout the aging process.

You can promote safe rind development by implementing a regular 6% salt wash every three days, which helps establish beneficial molds while preventing unwanted growth.

When working with mold-ripened cheeses, it's essential that you wash your hands thoroughly before and after handling to prevent cross-contamination and maintain the integrity of your aging cultures.

Cultivation Of Blue Cultures

Mastering the cultivation of blue cultures requires precise control over environmental conditions and consistent monitoring throughout the aging process.

You'll need to maintain initial aging temperatures at 52-53°F with 80% humidity, then shift to 42-43°F with 90% humidity for final aging. The key to successful blue culture development lies in proper aeration – you'll see the first signs of blue mold around day 8, with significant growth by day 11.

To encourage proper mold distribution, you must:

- Create evenly spaced holes (3/4"-1" apart) that penetrate about 2/3 into the cheese

- Turn your cheese daily during the first 21 days of aging

- Exchange fresh air once or twice daily to maintain oxygen levels

- Wipe away the surface mucosa before final aging

Throughout the 2-5 month aging period, you'll need to manage the interaction between bacteria, yeast, and mold.

These microorganisms work together to break down lactose and proteins, creating the distinctive flavors and crumbly texture of blue cheese. Remember to regularly scrape off excess exterior mold and watch for unwanted fungi that could compromise your cheese's quality.

Safe Rind Development Practices

While blue cheese cultivation focuses on internal mold development, proper rind management requires a different set of skills and practices.

You'll need to maintain precise environmental controls in your aging space, monitoring both temperature and humidity levels to encourage beneficial mold growth while preventing unwanted varieties.

For natural rind cheeses, you'll want to establish a regular maintenance schedule. This includes turning the wheels frequently, washing or brushing the surfaces as needed, and applying oil when appropriate.

If you're working with clothbound cheddars, you'll need to wrap them carefully in cheesecloth and apply butter or lard to promote healthy mold development.

Pay special attention to different rind types' unique requirements. Bloomy rinds need proper air circulation to avoid ammonia buildup, while washed rinds require regular bacterial cultivation using B-linens.

You'll find that consistent environmental conditions are vital for uniform rind development across all cheese types.

Remember that proper rind development isn't just about appearance – it's essential for flavor development and cheese protection.

While most rinds are safe to eat, you'll want to guide your customers on which ones enhance the tasting experience and which are better left aside.

Cheese Turning and Flipping Techniques

Proper turning and flipping of aging cheeses plays an essential role in achieving even ripening and ideal flavor development. You'll need to establish a consistent schedule, which may require turning your cheeses daily or even twice daily, depending on the variety. The frequency directly impacts moisture distribution and prevents uneven mold growth throughout the aging process.

To guarantee safe and effective turning, you'll want to use appropriate tools and methods. Secure your cheese molds with hose clamps and sushi mats, or utilize cheese boards fastened with stainless steel threaded rods. For softer varieties, flour sack towels or butter muslin can provide additional support during handling.

Monitor your cheese cave's temperature and humidity levels, as these environmental factors greatly influence the turning frequency and overall ripening process. You'll need to maintain proper hygiene and handle cheeses gently to prevent damage while checking their maturation progress.

- Picture a perfectly aligned row of cheese wheels, each carefully positioned on wooden boards

- Visualize the gentle lift and flip of a wheel, supported by a clean muslin cloth

- Imagine inspecting the developing rind for uniform coloration and texture

- See yourself recording the turning schedule in a detailed aging log

Surface Treatment and Rind Development

The art of surface treatment and rind development demands meticulous attention to both technique and environmental control.

You'll need to master various methods, from washing cheeses with brine to brushing natural rinds and applying substances like oils or herbs. For bloomy rind cheeses, you'll want to use vegetable ash to control surface acidity, while washed rind varieties require regular brine applications to cultivate specific bacteria and yeasts.

Your aging environment must maintain precise conditions. Keep temperatures between 55-60°F for soft cheeses and 40-55°F for hard varieties, while maintaining humidity levels between 90-98%.

You'll need to monitor dew points and guarantee proper air exchange to control moisture loss and support healthy microbial growth.

As you develop your aging skills, you'll learn to recognize and manage different rind types. Natural rinds need regular brushing to control mold growth, while washed rinds require frequent smearing to develop their characteristic aromas.

Watch for microbial succession and manage cheese mites, which can actually contribute positively to natural rind development.

Common Aging Problems and Solutions

You'll encounter three major challenges when aging fine cheeses: managing unwanted molds, dealing with temperature swings, and maintaining proper moisture levels.

To control mold growth, you need consistent air circulation and proper humidity levels, while temperature fluctuations can be minimized by using insulated aging spaces and monitoring systems.

For ideal moisture balance, you'll want to adjust your aging room's humidity based on cheese type, regularly turn your cheeses, and use appropriate wrapping techniques.

Mold Control Techniques

Successfully controlling mold during cheese aging requires a thorough approach that balances environmental conditions, production processes, handling practices, and quality control measures.

You'll need to maintain humidity levels between 85-95% while guaranteeing proper air circulation through your aging space. It's essential to monitor these conditions regularly using hygrometers and adjust ventilation systems accordingly.

Your production process starts with using high-quality pasteurized milk and maintaining precise pH levels throughout cheese-making. You'll want to pay special attention to salt concentrations during brining and guarantee proper whey drainage to prevent excess moisture that could lead to unwanted mold growth.

- Picture a pristine aging room with rows of wooden shelves holding carefully arranged wheels of cheese

- Visualize gleaming stainless steel hygrometers mounted on walls, displaying precise humidity readings

- See yourself wearing clean protective gear while carefully turning each cheese wheel

- Imagine a well-organized documentation station with detailed temperature and humidity logs

Remember to implement regular cleaning schedules, separate different cheese varieties to prevent cross-contamination, and conduct frequent microbiological testing.

You'll also need to maintain proper documentation through HACCP systems and address any signs of unwanted mold growth immediately.

Temperature Fluctuation Fixes

Maintaining steady temperatures stands as a critical challenge when aging fine cheeses, with even minor fluctuations potentially disrupting the delicate balance of enzymatic activity and flavor development.

You'll need to keep most cheeses between 10-15°C (50-59°F), though specific varieties like alpine and blue cheeses require different ranges.

To stabilize temperatures, start by properly insulating your cheese cave and adding thermal mass using water bottles.

You'll want to install a reliable temperature controller that offers precise adjustments within a narrow range.

Check temperatures twice daily and minimize opening the cave's door to prevent unwanted fluctuations.

If you're using a converted refrigerator, place your cheeses in the warmest section and maintain consistent settings.

Add humidity using a wet paper towel or shallow water pan, but make sure good air circulation to prevent cold spots.

When seasons change, you'll need to adjust your temperature controls accordingly.

Remember that temperatures below freezing can damage texture, while those above 60°C (140°F) will denature proteins.

Moisture Balance Strategies

One of the most essential elements in cheese aging involves striking the perfect moisture balance, as humidity levels directly impact texture, flavor development, and rind formation.

You'll need to carefully monitor and adjust humidity levels based on your cheese type, with soft-ripened varieties requiring 90-95% humidity and semi-hard cheeses needing 80-85%.

Too much moisture can lead to unwanted mold growth and surface slime, while insufficient humidity causes drying and cracking. You can prevent excess moisture issues by improving air circulation and wiping the cheese regularly with a brined cloth.

For cheeses that are too dry, try wrapping them in a slightly damp cloth or increasing the aging environment's humidity.

- Beads of moisture glistening on the cheese surface, indicating ideal humidity

- Fine white mold developing evenly across a perfectly formed rind

- Smooth, crack-free surfaces that reflect proper moisture balance

- Golden-hued rinds with slight elasticity when touched

Watch for signs of improper moisture levels during the aging process. If you notice uneven rind development or separation, adjust your humidity levels promptly.

Remember that different stages of aging may require different humidity levels, so stay vigilant and adapt your approach accordingly.

Testing Cheese Maturity

Testing cheese maturity calls for a combination of traditional sensory methods and modern technological approaches. You'll need to evaluate both visual indicators and conduct specific tests to guarantee your cheese has reached peak ripeness.

Start by examining the visual cues: look for appropriate color development, such as a deeper yellow in aged Gouda or evenly distributed blue-green veins in blue cheese. Check the rind formation – a properly developed bloomy rind on Brie indicates maturity. Notice texture changes, where soft cheeses become creamy and hard cheeses develop a crumbly consistency.

For more precise assessment, you can use mechanical testing methods. A penetration test with cylinder or cone probes will measure firmness, while a cheese trier allows you to extract samples from large wheels.

If you're working in a professional setting, you'll benefit from advanced technologies like NIR hyperspectral imaging, which predicts maturity by analyzing spectral data.

Remember to maintain proper environmental conditions throughout testing: keep temperatures between 50-55°F (10-13°C) and humidity at 80-90% for most cheeses.

For non-pasteurized varieties, guarantee aging for at least 60 days at 4°C to prevent pathogen growth.

Natural Versus Controlled Aging

When deciding between natural cave aging and modern climate control for your fine cheeses, you'll need to weigh the trade-offs between traditional character and consistency.

While cave-aged cheeses develop unique flavors from wild microbial communities and natural environmental variations, modern climate-controlled environments offer more predictable outcomes and lower risk of spoilage.

You'll find that controlled aging with lab cultures gives you precise command over the aging process, though some artisanal cheesemakers prefer the distinctive terroir that only traditional methods can achieve.

Traditional Cave Vs Modern

The debate between traditional cave aging and modern controlled environments represents a fascinating intersection of heritage and innovation in cheese making.

In traditional caves, you'll find cheeses resting on wooden boards in high-humidity environments above 90%, where natural molds flourish and enhance flavors. These caves, particularly common in central Italy, offer consistent temperatures and unique microclimatic conditions that shape the cheese's character.

Modern controlled aging, however, gives you precise control over every environmental factor. You can monitor temperature, humidity, and airflow while maintaining strict quality controls. This approach allows for consistent results and efficient production, with reduced risk of contamination.

Picture these contrasting scenes:

- Ancient limestone caves with wooden shelves lined with aging wheels, their rinds developing a natural patina

- Cheese wheels gently turned by hand and lovingly rubbed with olive oil

- Pristine steel aging rooms with digital monitors tracking every environmental variable

- Rows of perfectly aligned cheeses under controlled lighting and ventilation

While modern methods offer reliability and scalability, traditional cave aging imparts unique terroir-driven characteristics that many cheese connoisseurs still prize.

Each approach serves its purpose in today's diverse cheese-making landscape.

Climate Control Benefits

Every cheese artisan must weigh the distinct advantages of natural and controlled aging environments when crafting their perfect wheel.

While natural caves offer authentic microbial flora and traditional aging conditions, controlled environments provide you with precision and consistency that's hard to match.

You'll find that controlled aging rooms let you fine-tune temperature between 45°F and 60°F, while maintaining exact humidity levels for different cheese varieties.

Unlike caves, where conditions fluctuate naturally, you can customize every aspect of the aging process to match your cheese's specific needs. This level of control helps you prevent spoilage and achieve consistent results across batches.

When you're working with controlled environments, you'll be able to accelerate or slow down aging by adjusting conditions precisely.

You can also introduce specific cultures and manage microbial activity more effectively than in natural settings.

While cave-aged cheeses develop unique characteristics from their environment's natural flora, your climate-controlled space gives you the power to replicate desired conditions repeatedly.

This means you'll produce more predictable outcomes and maintain higher quality standards across your production, though you might sacrifice some of the distinctive qualities that natural aging provides.

Wild Vs Lab Cultures

Building on the precision of climate control, your choice between wild and lab cultures represents another key decision in cheese aging. While wild cultures occur naturally and can create unique, complex flavors, they're less predictable and require extensive expertise to manage. Lab cultures offer consistency and reliability, making them ideal for controlled aging processes and commercial production.

You'll find wild cultures create distinctive regional characteristics in your cheese, developing intense flavors over time through complex microbial ecosystems. However, they demand careful monitoring and present higher contamination risks. In contrast, lab cultures give you precise control over fermentation and aging, ensuring uniform results and predictable flavor profiles.

Picture the aging process with wild cultures:

- Rustic wooden shelves lined with artisanal cheeses, each developing its unique character

- Natural rinds forming with subtle variations in color and texture

- Traditional brushing and washing techniques passed down through generations

- Carefully monitored aging rooms filled with the earthy aroma of naturally developing cultures

Whether you choose wild or lab cultures depends on your goals: If you're seeking consistency and reliability, lab cultures are your answer. For unique, traditional character and complexity, wild cultures offer unmatched potential despite their challenges.

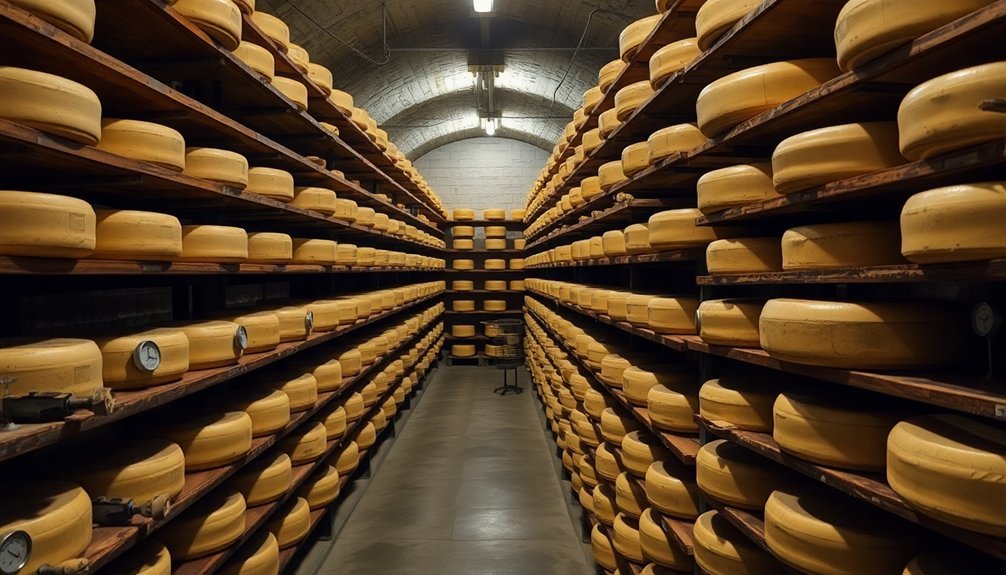

Equipment for Professional Aging

Professional cheese aging demands specialized equipment built up to exacting standards. At the heart of any aging operation, you'll find professional aging cabinets made from AISI 304 stainless steel and insulated with high-density polyurethane foam.

These cabinets aren't just refrigerators; they're sophisticated environments with electronic regulation systems controlling temperature, humidity, and airflow.

You'll need precise temperature control, typically maintaining around 50 degrees Fahrenheit, paired with humidity sensors to prevent your cheese from drying out or developing unwanted mold.

The ventilation system must provide indirect, homogeneous air circulation across all shelves, ensuring uniform aging throughout your cheese collection.

Don't overlook essential accessories that make a difference in your aging success. You'll want drainage trays and nylon mesh mats to manage excess moisture, and you might consider wooden shelves – particularly spruce – for certain cheese varieties.

If you're working with interior-ripened cheeses, you'll need cheese covers or bandages to control surface aging. For the most precise control, consider systems with SmartAging® technology, which can replicate professional cheese cellar conditions and allow you to program specific ripening cycles for different cheese types.

Frequently Asked Questions

Can Aged Cheese Be Vacuum-Sealed During the Aging Process?

Yes, you can vacuum-seal aged cheese, but you'll need to pre-age it for about 1.5 months first. While it's convenient, be aware it might affect flavor and texture compared to traditional aging methods.

How Does Music or Sound Vibration Affect Cheese Aging?

Sound waves can affect your cheese's metabolic processes during aging. You'll notice milder flavors with most music, but hip-hop exposure creates stronger, fruitier notes, while low frequencies produce sweeter-tasting cheese.

What Materials Should Cheese Aging Shelves Be Made From?

You'll get the best results using wooden shelves, particularly pine, ash, beech, or spruce boards. They'll regulate moisture and support beneficial microbes. Just avoid exotic woods, cedar, and mahogany, which can harm your cheese.

Does Artificial Lighting Affect the Quality of Aging Cheese?

While there's no conclusive evidence about artificial lighting's effects on aging cheese, you'll want to minimize light exposure as a precaution. Focus instead on maintaining proper temperature, humidity, and air circulation in your aging space.

Can Multiple Cheese Varieties Be Aged in the Same Cave Together?

You can age multiple cheese varieties together, but you'll need to carefully consider their aging requirements. It's best to group cheeses with similar temperature, humidity, and microbial needs to prevent cross-contamination.

In Summary

You're now equipped to transform fresh cheeses into complex, aged masterpieces. Whether you're working with a small home setup or professional cave, you've learned the critical balance of temperature, humidity, and microbial management. Don't forget to monitor salt levels and regularly test for maturity. With practice and patience, you'll master the delicate art of aging cheese and create flavors that rival artisanal producers.

Leave a Reply