You'll find three proven DIY smokehouse building methods that have stood the test of time. The block and concrete foundation method offers superior stability by connecting the firebox to the smoke chamber with metal piping set in concrete. The wooden post frame construction provides a cost-effective approach using construction-grade lumber and precise post placement below the frost line. The hybrid stone and timber design combines fieldstone walls with a timber octagon roof for ultimate durability and fire safety. Each method brings unique advantages to help you create a lasting structure that'll serve up perfectly smoked meats for generations to come.

Block and Concrete Foundation Method

You'll need to connect your firebox to the smoke chamber using an 8-inch metal chimney pipe, positioning it 10-12 inches below the floor and 8-10 feet from the center hole.

Install this pipe before pouring your concrete floor.

Ensuring proper ventilation and airflow is crucial for optimal smoking conditions.

Finally, frame your roof with evenly spaced rafters, add shingles, and build a header with cement and rebar for extra durability.

Wooden Post Frame Construction

Along with proper planning, successful wooden post frame construction begins with accurate post placement. You'll need to dig holes below the frost line, set oversized posts, and use temporary braces to keep them plumb.

After securing the posts upright, cut them to level heights and verify square corners by measuring diagonal distances. Install temporary 2×6 braces along the bottom to maintain straight lines.

For the upper structure, guarantee your long walls remain parallel by measuring the building's width at both ends. Cut and test your rafters at multiple points before securing them to the ridge board with deck screws. A 24-rafter system provides optimal support for the roof structure.

Pre-drill holes for 8-inch spikes to anchor the rafter bottoms, and add blocking between rafters for structural support and pest prevention.

Use 1½-inch construction-grade lumber for wall sheathing to prevent flexing and extend the building's lifespan.

When setting posts, pack them with soil rather than concrete to avoid rot and frost heaving. Consider cedar or locust posts for natural rot resistance.

Space your posts widely to minimize waste when installing wall boards and guarantee efficient construction.

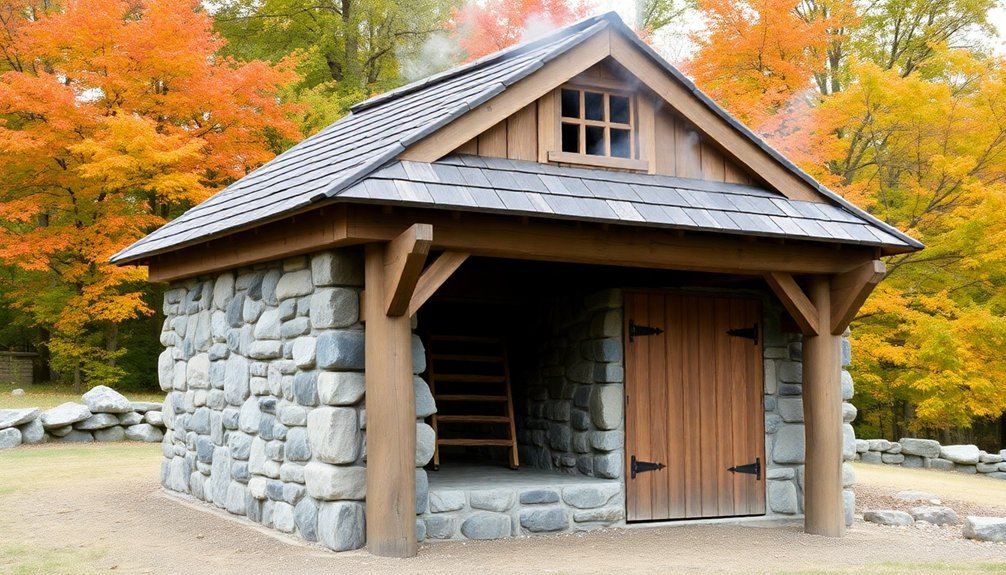

Hybrid Stone and Timber Design

Three key principles define a successful hybrid stone and timber smokehouse: durability, fire safety, and proper smoke flow. You'll achieve these by combining fieldstone walls with a timber octagon roof, all set upon a frost-line-depth concrete foundation. When building, verify your corners align perfectly by measuring diagonal distances and using support posts strategically. This design requires thick stone walls of approximately 18 inches for optimal insulation.

| Component | Material | Key Feature |

|---|---|---|

| Walls | Fieldstone | Fire-resistant |

| Roof | Timber | Octagon design |

| Firebox | Stone/Concrete | Detached placement |

For ideal smoke circulation, position your detached firebox at least 4 inches from the main structure, maintaining a 30-degree angle for the smoke channel. The smoke hole in your firebox should sit lower than the smokehouse floor's smoke hole to create natural upward flow. You'll want to use stainless steel for your chimney rather than galvanized materials to prevent food contamination.

Don't forget to install blocking between your rafters and secure them tightly to the wall with a ridge board in between. Your foundation must extend below the frost line, and placing the structure on a knoll will enhance ventilation while protecting against ground moisture.

Frequently Asked Questions

How Long Should Wood Cure Before Using It in Smokehouse Construction?

You'll need to cure your wood for about 4 months before using it in smokehouse construction. Make sure it reaches a moisture content of 20% or less through air drying or kiln drying methods.

What's the Ideal Distance Between Smokehouse and Nearby Buildings for Safety?

You'll need to maintain at least 15 feet between your smokehouse and any nearby buildings. This distance guarantees fire safety and complies with standard regulations while providing adequate space for ventilation and access.

Can Old Barn Materials Be Safely Repurposed for Smokehouse Construction?

You can reuse old barn wood if it's untreated and chemical-free, but avoid any pressure-treated lumber, painted materials, or rotted pieces. Test wood carefully for contamination before using it in your smokehouse construction.

How Often Should Smoke Generator Parts Be Cleaned and Maintained?

You'll need to clean your smoke generator daily for leaks and fluids, monthly for batteries and oil, and annually for thorough maintenance. Don't skip weekly inspections of the exhaust system and unusual sounds.

What Types of Paint or Sealants Are Food-Safe for Interior Surfaces?

You'll need FDA-certified food-grade paints like Fakolith FoodGrade or water-based epoxies with BioFilmStop technology. Make sure they're fully cured before use, and consider natural oils like tung or walnut for additional protection.

In Summary

You've got three fantastic options for building a traditional smokehouse that'll serve you well for years to come. Whether you choose the durability of block and concrete, the simplicity of wooden post frame, or the rustic appeal of stone and timber, just remember to focus on proper ventilation and temperature control. Now you're ready to start smoking your own meats and preserving food like your ancestors did.

Leave a Reply